There are countless types of optical fibers designed for specific functions beyond general communication transmission. While standard fibers efficiently transmit light signals over long distances, specialty fibers allow you to manipulate light in innovative ways through customized properties.

These unique fibers open up possibilities like amplifying signals, preserving polarization, compensating dispersion, and more. Whether you need to couple high-power lasers, sense physical parameters, or process signals, there’s likely a specialty fiber suited for your application.

In this guide, we’ll overview some of the most common specialty fiber types and their novel capabilities. Understanding these optical wonders can spark ideas for leveraging light in unconventional ways.

Table of Contents

Erbium-Doped Fiber

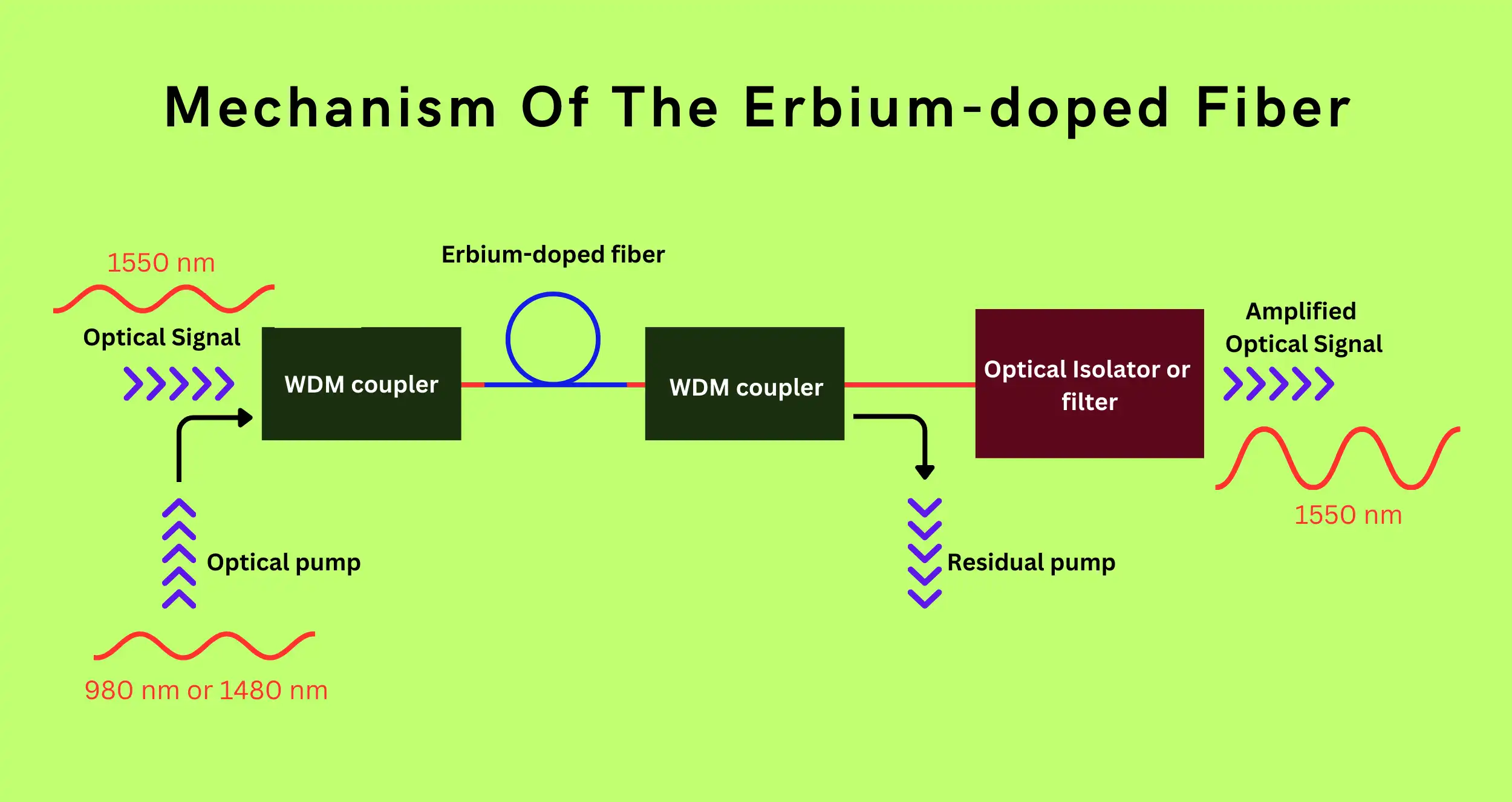

Erbium-doped fibers give optical signals a boost through a process called gain. They work by doping the silica glass material with erbium ions, which interact with light to provide optical amplification.

A typical erbium-doped fiber length is 10 to 30 meters. This active medium is pumped with light around 980 nm or 1480 nm to activate the erbium ions. The ions then amplify signals in the C-band from 1530 to 1565 nm, which is commonly used in optical communications.

Key advantages:

- Allow transmission over 80-100 km without repeaters

- Increase bandwidth substantially in networks

- Used to make fiber amplifiers like EDFAs and fiber lasers

- Compatible with broadband standards like DWDM

EDFAs (Erbium-Doped Fiber Amplifiers) are a key technology enabled by these special fibers. EDFAs are deployed extensively in backbone networks to amplify signals over long hauls without optical-electrical-optical conversion.

The combination of erbium doping and fiber as the gain medium produces high gain with low noise. And unlike electrical repeaters, EDFAs can simultaneously amplify multiple wavelength channels, supporting the expansion of network capacity.

So, if you need to send signals farther or increase bandwidth, consider pumping up your capabilities with erbium-doped fibers!

Photosensitive Fiber

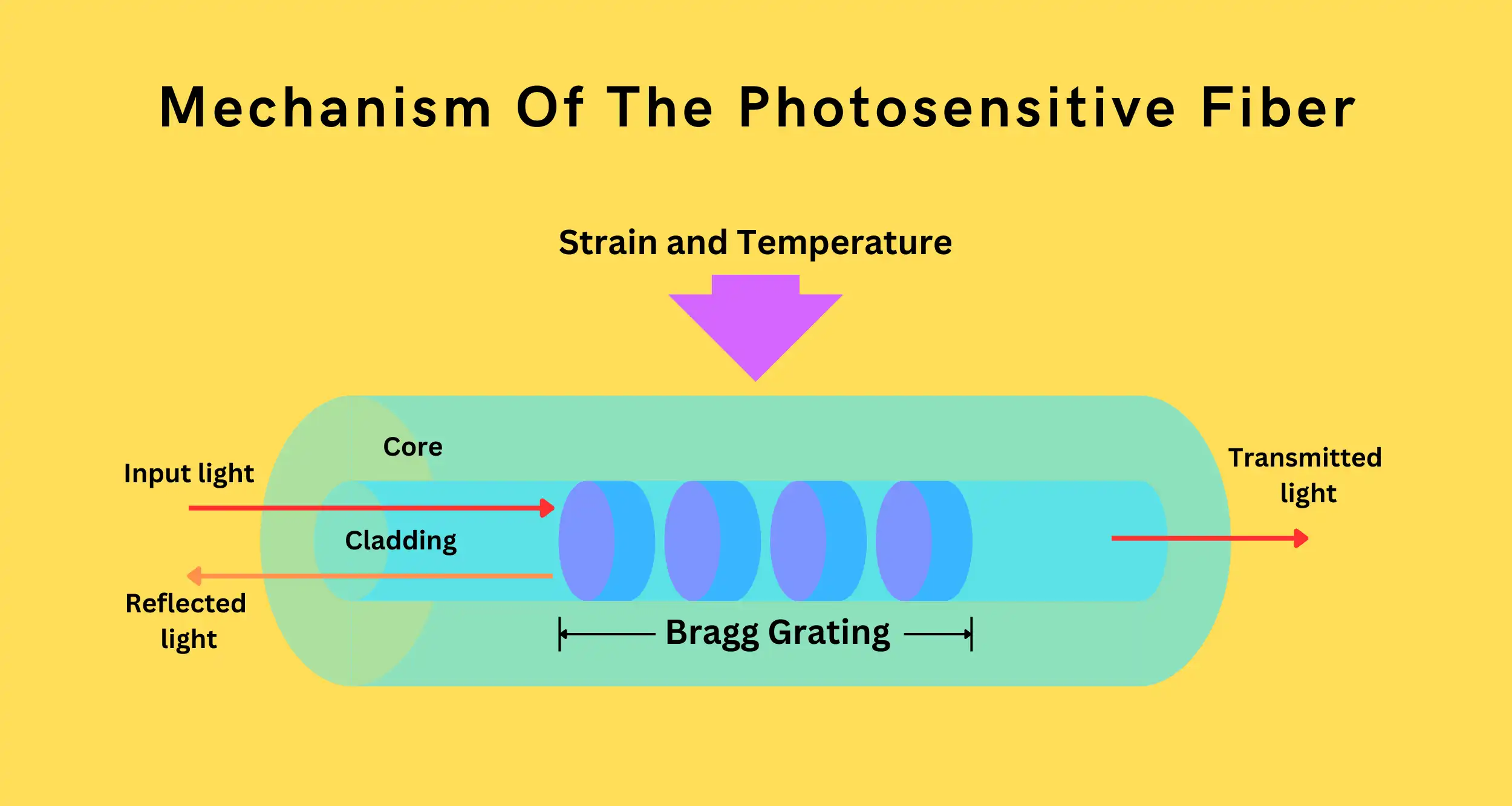

Photosensitive fibers give you custom control over the refractive index profile through exposure to light. By modulating the UV exposure along the length, refractive index changes can be imprinted into the core.

This allows the creation of key devices like fiber Bragg gratings (FBGs). FBGs are periodic variations in the index that act as wavelength-selective mirrors.

Key FBG applications:

- Add/drop filters for DWDM

- Dispersion compensation modules

- Optical filters with tuned wavelengths

- Light coupling mechanisms for pump lasers

FBGs engraved in photosensitive fibers are crucial for manipulating signals in wavelength division multiplexed networks. They enable the dropping and inserting of specific wavelength channels.

Other uses:

- Optical taps for power monitoring

- Gain equalizing filters

- Stabilizing laser cavities

- Distributed sensing of temperature and strain

So if you need custom optical filters or sensing functions, photosensitive fibers offer the flexibility to permanently define the index landscape through exposure.

Polarization-Preserving Fiber

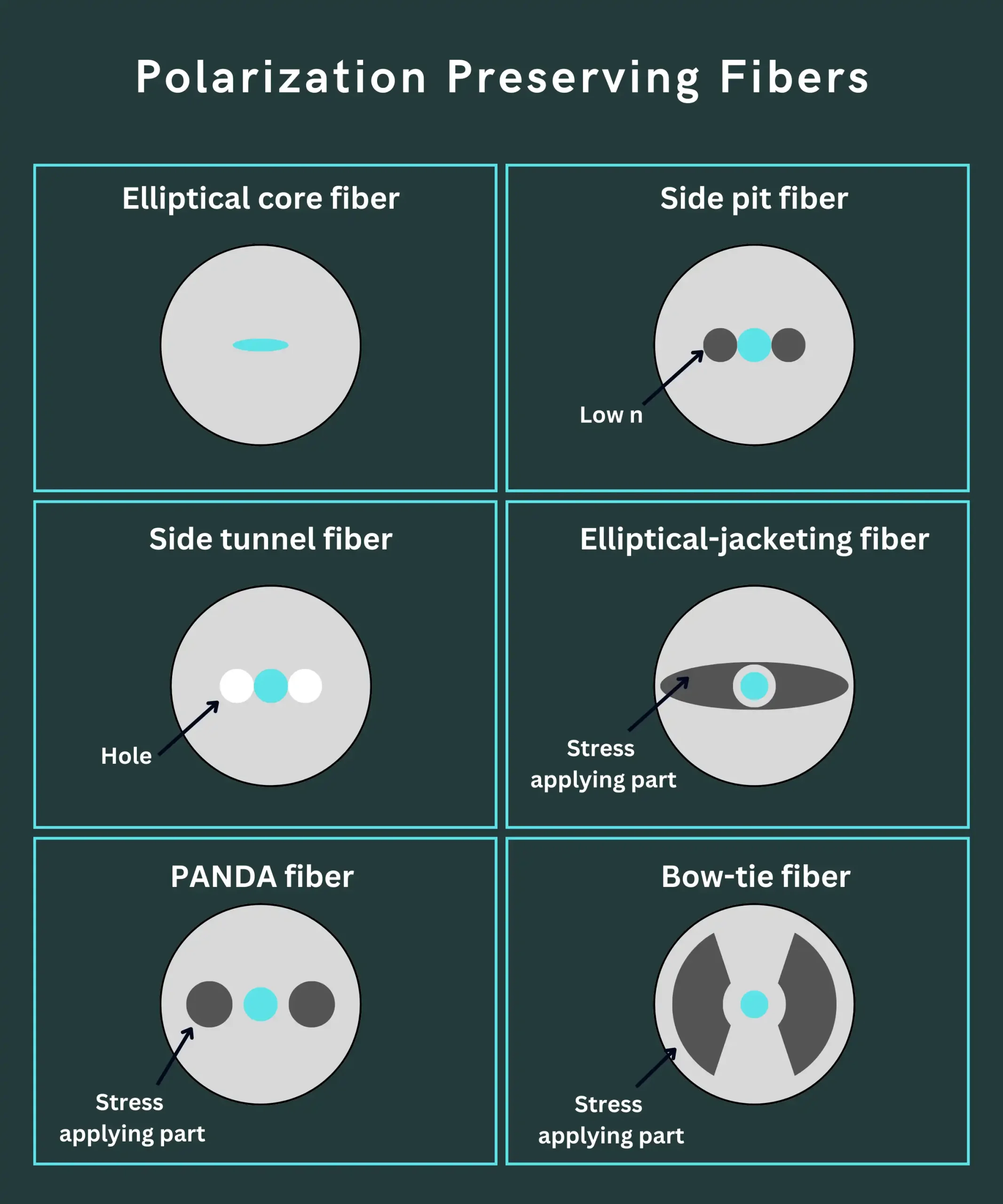

Polarization-preserving fiber is designed to maintain the polarization state of light as it travels through the fiber. Unlike standard fibers, where polarization randomly fluctuates, these specialty fibers keep the light uniformly oriented.

Preserving polarization is critical for technologies like:

- Fiber optic sensing to detect movement and other environmental factors

- Interferometry using superimposed light for precision measurements

- Quantum cryptography based on photon spin encoding

The fiber structure creates strong birefringence to prevent coupling between orthogonal polarizations. Common designs use stress-applying rods or an elliptical core shape.

With a consistent polarization output, these fibers enhance the precision of interferometers, gyros, and quantum cryptography systems. Polarization maintenance also improves fiber laser efficiency and fiber-based modulation.

By preserving the orientation of light, polarization-maintaining fiber enables greater precision and performance across a range of advanced applications.

Holey Fiber

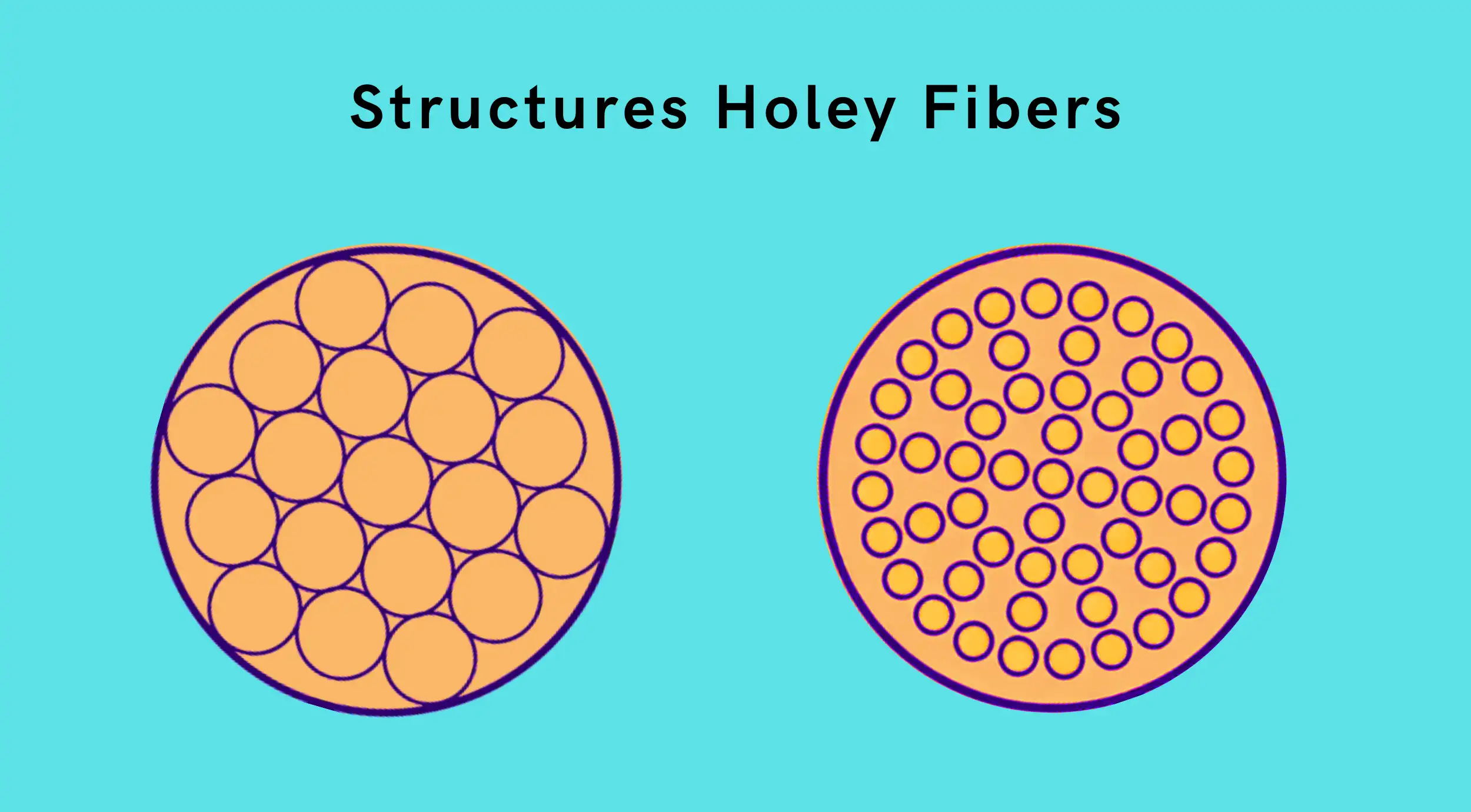

Holey fiber, also known as photonic crystal fiber, contains many microscopic air holes running along its length. The holes form a periodic pattern that acts as a cladding around a solid or hollow core.

The air holes lower the effective refractive index of the cladding compared to the higher index core. This allows light to be guided along the fiber core.

Potential applications of holey fiber include:

- Dispersion compensation to reduce signal distortion

- Wavelength conversion for flexible networking

- Optical switching to dynamically redirect signals

- High power amplification due to large mode areas

Holey fibers represent an emerging technology still under active development. Different arrangements of air hole size, spacing, and number provide unique capabilities.

Photonic crystal fibers like holey fiber confine light by band gap effects rather than total internal reflection. Other types include photonic bandgap, Bragg, and hole-assisted fibers.

With innovations in air hole structuring, holey fibers will unlock new feats in bandwidth, switching, amplification, and nonlinear optics.

High-Index Fiber

High-index fibers contain a core with a higher refractive index than standard fiber. This increases the fiber’s numerical aperture.

The larger numerical aperture allows optical power to be coupled into the fiber core more efficiently. This makes high-index fiber ideal for connecting to high-power laser sources.

A short 1-meter “pigtail” of high-index fiber can be directly attached to a laser diode or other optical source. This eliminates coupling loss between standard fiber and source.

High-index fibers are optimized for:

- Short-wavelength visible sources

- Long-wavelength IR sources

- Fused fiber couplers and multiplexers

Specialty high-index fibers meet specific needs that standard communication fiber cannot. Performance factors like numerical aperture, wavelength, loss, and bending are all engineered for custom applications.

High-index fibers provide efficient coupling and beam control across visible and infrared wavelengths by tailoring the core index and geometry.

Bend-Insensitive Fiber

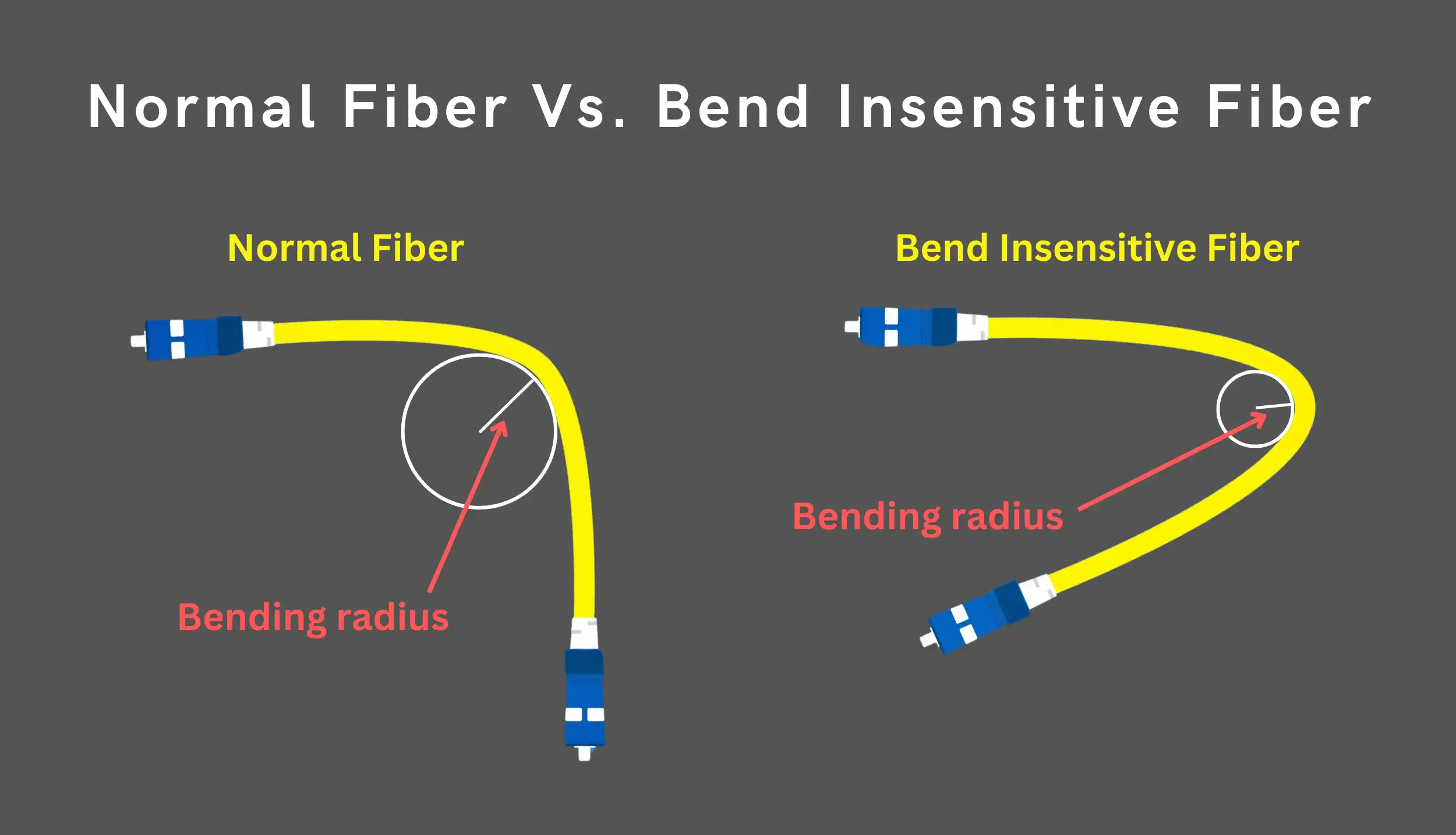

Bend-insensitive fiber is engineered to maintain low optical loss when bent around tight radii. This is unlike standard fiber which fails at small bend radii.

To achieve bend resistance, these fibers use a higher numerical aperture to strongly confine light in the core. This prevents bending losses.

Design types include:

- Small core fiber – Improves bend performance but with some compatibility issues

- Trench-assisted – Combines bend insensitivity with compatibility to standard fiber

- Void-assisted – Voids around the core act as low-index cladding

- Optimized matched/depressed cladding – Provides moderate bend improvement and compatibility

Key factors for bend-insensitive fiber include macro bending loss, operating wavelength, and compatibility with standard fiber.

Bend-insensitive cables are commonly used in data centers, ceilings, floors, and other tight spaces. They prevent failures and signal loss when routing fiber through small conduits and enclosures.

With flexibility and durability, bend-insensitive fiber enables new applications in fiber management across many industries.

Double-Clad And Triple-Clad Fibers

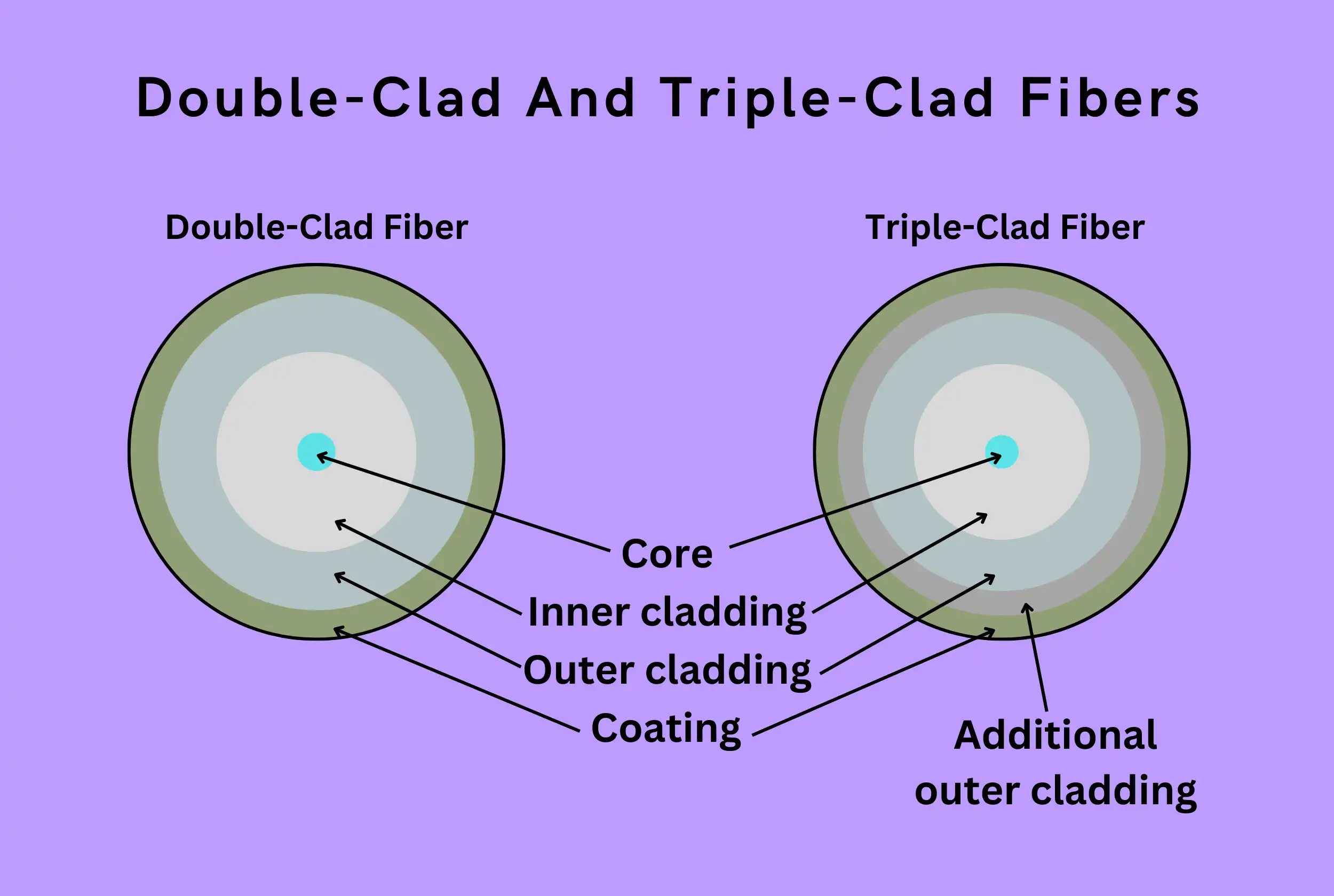

Double-clad fibers contain 3 layers – core, inner cladding, and outer cladding. This provides two separate waveguides – the core guides signals while the inner cladding guides pump light.

- Core diameter: 5-15 μm

- Inner cladding diameter: 100-400 μm

- Outer cladding absorbs pump cladding modes

Key benefits:

- Pump cladding enables high-power fiber lasers/amplifiers

- Reduce bend losses for high-power delivery

- Efficient coupling of pump diode light

- Handling capability up to 10 kW

Triple-clad fibers add another outer cladding layer to confine pump light leakage:

- Provides all-glass double-clad structure

- An extra degree of freedom for optimization

So if you need high-power handling, double-clad or triple-clad fibers offer superior pump integration and beam delivery.

Large Mode Area Fibers

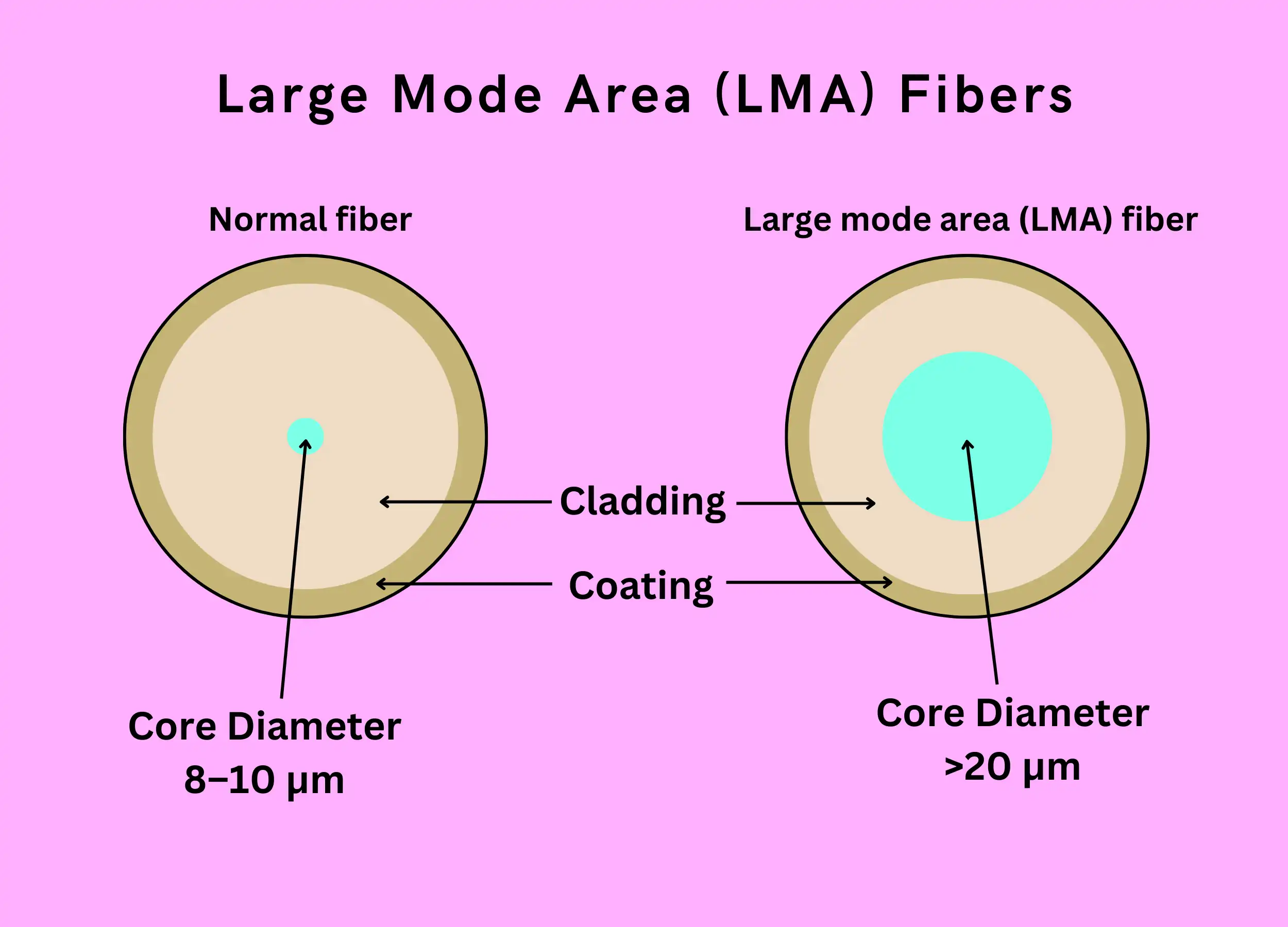

Large mode area (LMA) fibers contain a large core diameter compared to standard single-mode fiber.

- Typical core diameter: >20 μm

- Low numerical aperture: 0.05-0.1

Benefits:

- Increased damage threshold for high-power

- Reduced nonlinear effects like Kerr

- Enable pulsed amplification up to kW levels

Applications:

- High-energy fiber lasers

- Amplifiers for high-power signals

- Nonlinear devices like supercontinuum sources

LMA fibers balance single-mode operation with a large light-guiding area. This provides exceptional performance for high peak and average power delivery.

So when conventional fibers fail at high power densities, they turn to large-mode area fibers to guide intense light.

Highly Nonlinear Fibers

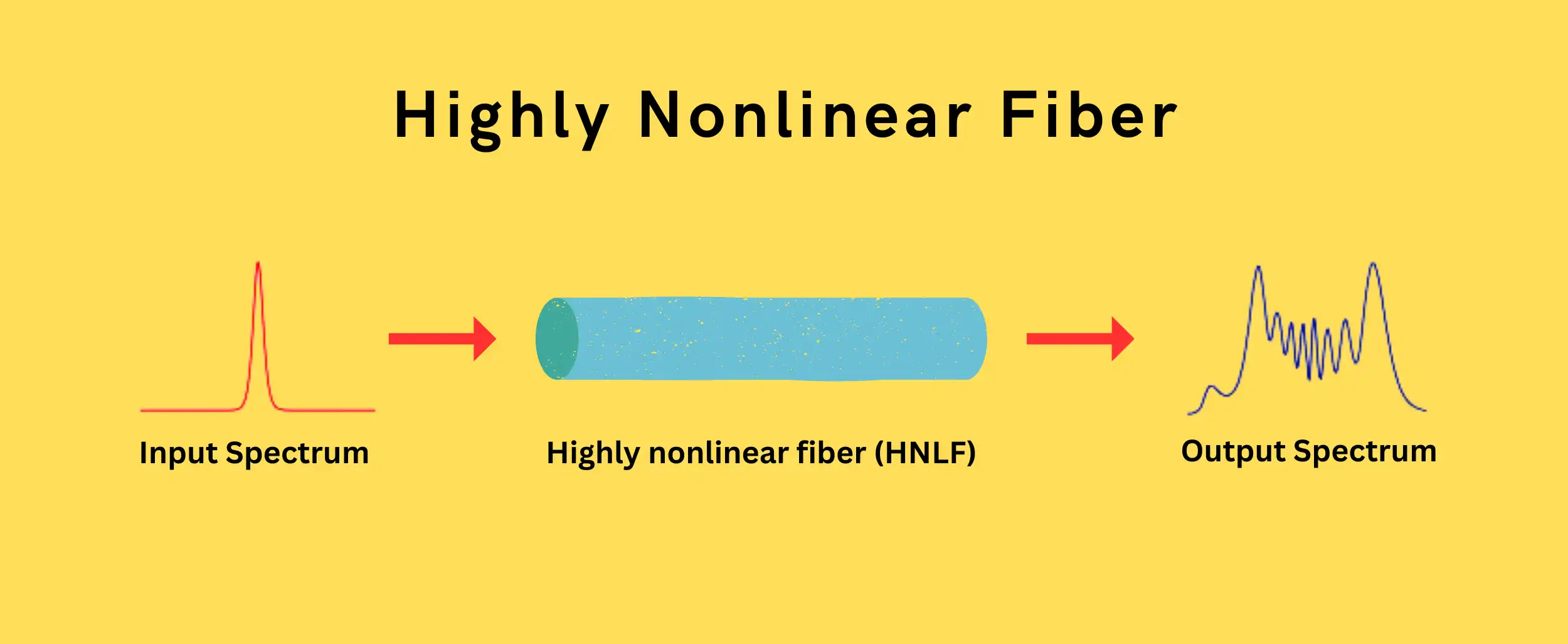

Highly nonlinear fibers (HNLFs) contain design properties to maximize nonlinear optical effects. This allows efficient nonlinear processes like:

- Supercontinuum generation

- Four-wave mixing

- Parametric amplification

Typical properties:

- Small effective area: <10 μm2

- High nonlinear coefficient: 10 /W/km

- Near zero dispersion at 1550 nm

- Low attenuation < 1 dB/km

Key applications:

- Spectral broadening for femtosecond lasers

- Wavelength conversion for telecom

- Pulse compression of ultrashort pulses

So if you need strong nonlinear interactions between multiple wavelengths, use highly nonlinear fibers to efficiently mix and process light.

Raman Gain Fibers

Raman gain fibers utilize Raman scattering to amplify input signals and generate new wavelengths.

- Pump wavelength < signal wavelength

- Power transfer from the pump to Stokes wave

Key parameters:

- Composition (GeO2 concentration)

- Core and cladding design

- Length (up to 10+ km)

Benefits

- Gain bandwidth > 100 nm

- Broadband amplification

- Low noise figure

- No excited state lifetime issues

Applications:

- Distributed amplification in networks

- Raman lasers and amplifiers

- Sensing using Stokes/anti-Stokes ratios

For wideband amplification or remote delivery, Raman gain fibers offer high performance by harnessing the Raman effect.

Conclusion

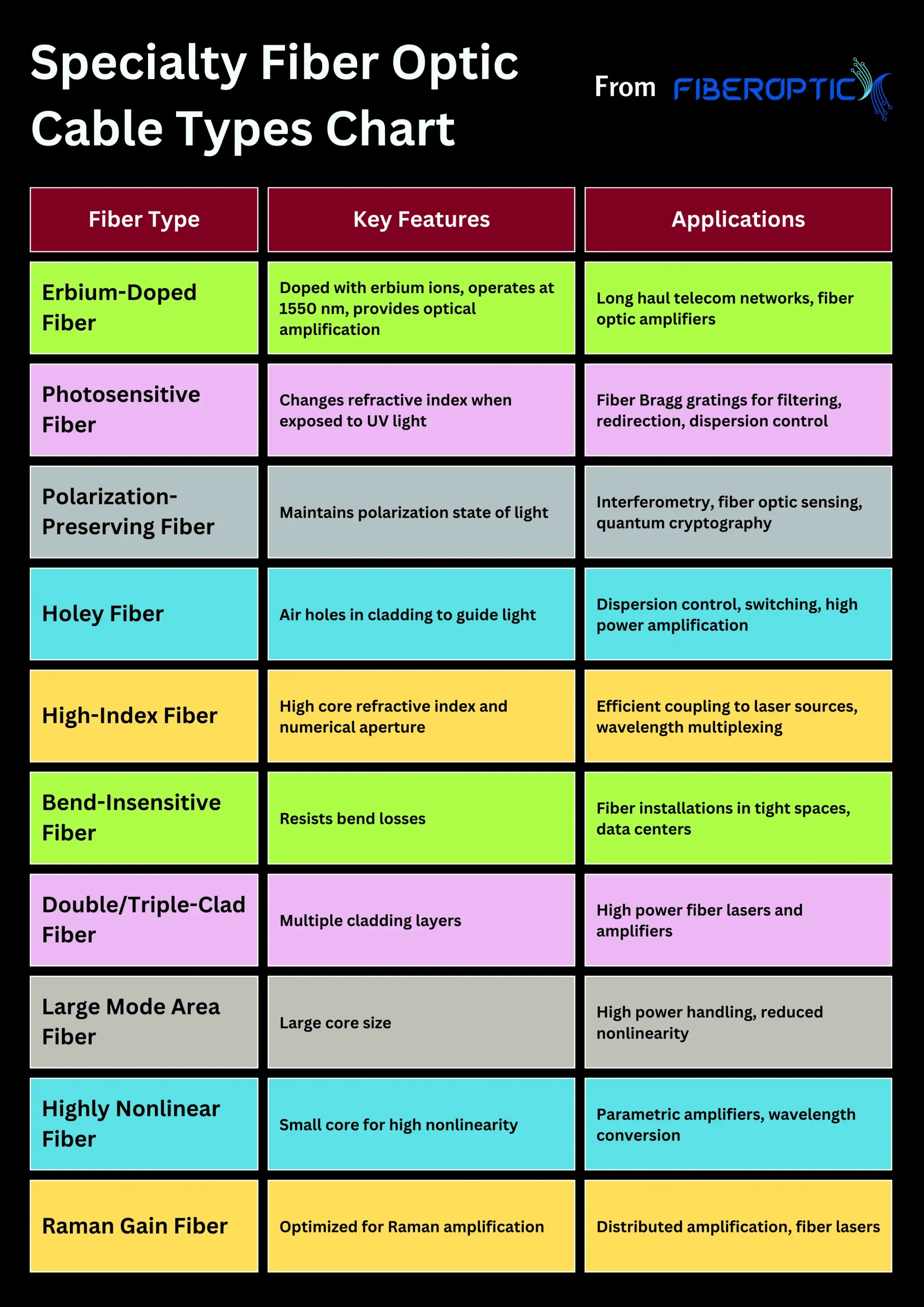

Here is the comparison chart of specialty fiber optic cable types discussed above.

Other than indoor fibers and outdoor fibers, specialty optical fibers empower you to manipulate light in diverse ways through engineered waveguiding structures. Whether you need gain, nonlinearities, dispersion control, or modal properties like large areas or single polarization, there’s a specialty fiber designed to deliver.

Erbium-doped fibers provide crucial amplification for long-haul networks and high-speed communications. Photosensitive fibers enable customized light coupling, filtering, and sensing via UV-defined fiber Bragg gratings.

Polarization-maintaining fibers ensure a constant polarization state for interferometry and sensing. Holey and nonlinear fibers facilitate dispersion tailoring and strong nonlinear interactions.

For high power needs, double-clad, triple-clad, and large-mode area fibers guide intense light while minimizing nonlinear effects. And Raman gain fibers unlock distributed broadband amplification through the Raman effect.

As new fiber innovations arise, additional possibilities will emerge for shaping light propagation. However the specialty optical fibers covered here already provide a versatile toolkit for efficiently manipulating optical waves.

So explore how these unique fibers can enhance your current and future applications. With the right specialty fiber, you can overcome limitations and discover new ways to harness the power of light.

FAQ

What are the different types of specialty fibers?

Specialty optical fibers are designed to perform specific functions that standard optical fibers cannot. These include polarization-maintaining fibers, which preserve the polarization of light; photonic crystal fibers, which can guide light by diffraction from a periodic structure; multicore fibers, which have multiple cores in a single fiber; and plastic optical fibers, which are made from plastic instead of glass.

Which type of optical fiber is best?

Single-mode fibers are best for long-distance transmission because they have a high bandwidth and low attenuation. Multimode fibers are best for short-distance transmission because they are less expensive and easier to work with. Plastic optical fibers are best for applications requiring flexibility and environmental resistance.

What are the two most popular optical fiber materials?

The two most popular materials for optical fibers are silica and plastic. Silica is used for both single-mode and multimode fibers because of its low attenuation and high optical quality. Plastic is used for plastic optical fibers because it is flexible and resistant to environmental conditions.

What are the applications of specialty optical fibers?

Specialty optical fibers have a wide range of applications beyond traditional telecommunications. Some exciting examples include:

Medical imaging: Hollow-core fibers guide high-power lasers used in medical procedures like laser ablation and tissue welding.

Sensors: Photonic crystal fibers can be used to sense chemicals, temperature, and strain, making them valuable for environmental monitoring and structural health monitoring.

Quantum technologies: Multi-core fibers enable quantum communication and computing by transmitting entangled photons.

Defense and security: Active fibers are used in high-power lasers for military applications, and polarization-maintaining fibers are crucial for secure communication systems.

What is the specialty of guided mode?

Guided mode refers to the propagation of light in a way that it remains confined within the fiber. The specialty of guided mode is that it allows for long-distance transmission of light with minimal loss of signal strength. This is achieved through the phenomenon of total internal reflection, where the light is continually reflected off the walls of the fiber and guided along its length.