I assume that you all know that there are mainly two types of optical fiber. The two main types of optical fiber are classified as Multimode fibers and Singlemode fibers.

This classification is mainly built on the light transmission mode inside the fiber. By the way, we can classify optical fibers in many ways. In this article, I will present to you the types of optical fiber based on material.

Table of Contents

What material is the optical fiber

Optical fibers are mainly made using silica-based glass (SiO2) or plastic. Also, we can use glass and plastic mix medium for fiber manufacturing.

The medium for making these fibers varies according to different requirements like transmission distance, attenuation, and handling of fiber. Finally, there are three types of optical fiber based on material.

- Glass optical fiber

- Plastic optical fiber

- Glass-plastic optical fiber

Selection of material for fiber optics

When selecting fiber material, we have to consider the material-based requirements. There are three basic criteria for selecting materials for manufacturing fiber. Let’s have a look at them one by one.

- It must be possible to make long, thin, and flexible fiber from the selected material.

This is the main requirement for making optical fiber for long-distance transmission. The thinness and flexibility are the most considerable part when choosing material for making optical fiber.

- The selected material must be transparent at a particular optical wavelength.

When you choose any material for optical fiber, it should be very clear since the clearness of the material makes less attenuation.

- The selected material must be physically compatible and have slightly different refractive indexes for the core and cladding.

You should choose a physically compatible material with a slightly different refractive index for the core and cladding. The reflective index of the core must be greater than the reflective index of the cladding (Core > Cladding).

Glass optical fiber

As the name suggests, glass optical fiber is made using glass. Both core and cladding are made using ultrapure ultra-transparent silicon dioxide (SiO2) or fused quartz.

Glass has the inherent effect of refracting light. In glass fiber, we achieve total internal refraction to keep the light enclosed and traveling along the fiber optic cable.

Impurities are purposely added when making glass optical fibers to archive the expected reflection index. You can add germanium or phosphorus to increase the reflection index of the glass. Or else you can add boron or fluorine as doping to decrease the reflection index of the glass.

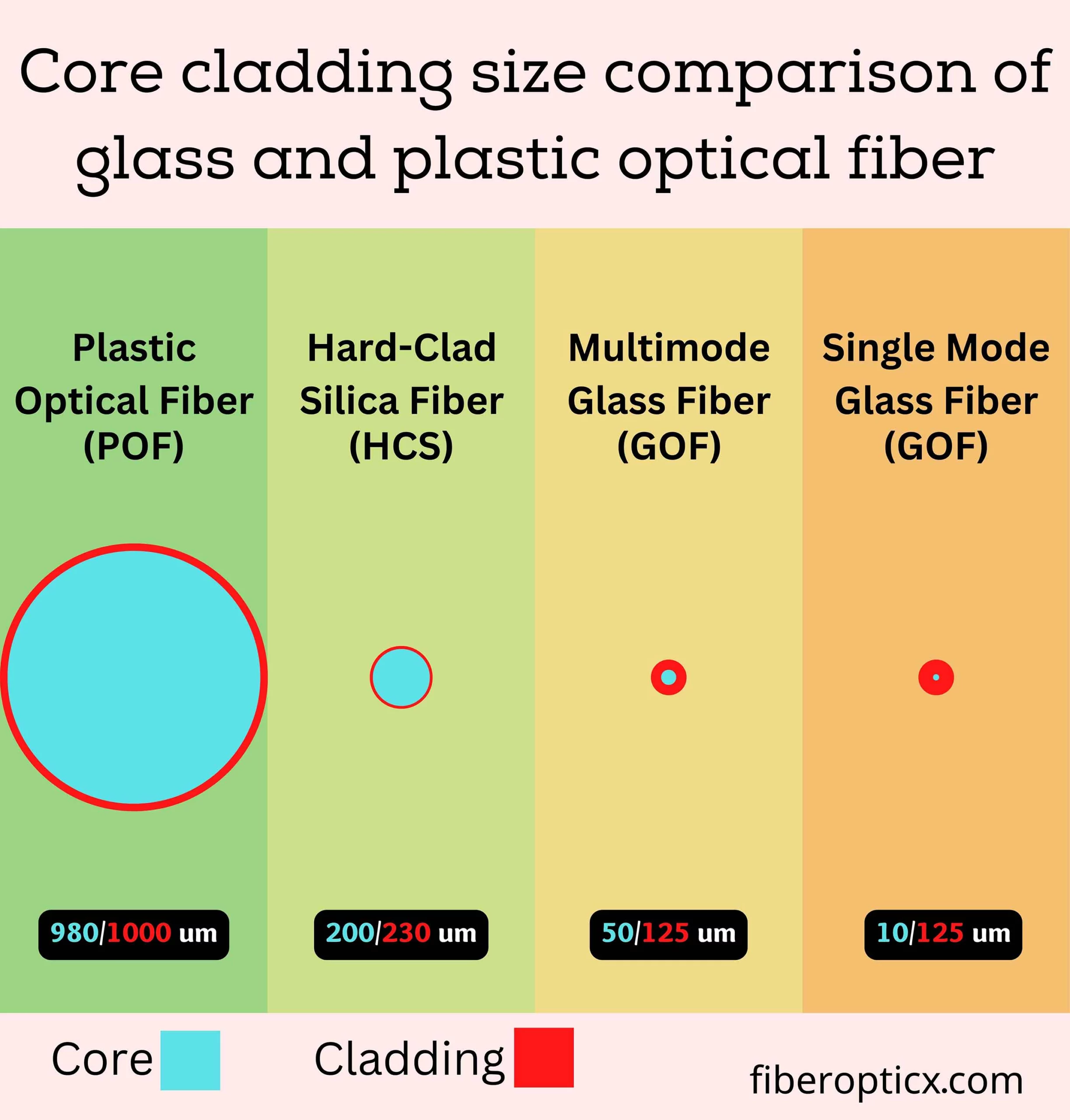

The thinnest fiber type is glass fiber. It is nearly about 0.002 inches or 50 microns in diameter. There are many advantages of glass optical fibers, but in comparison to plastic optical fiber, there are some drawbacks.

Advantages of glass optical fibers

- Glass fiber networks usually show fewer losses and have high data transmission capacity.

- You can use glass fiber in extreme-temperature environments such as furnaces and heat wave-emitting equipment. Also, it can be used in low-temperature sites (from -40∘F to 900∘F).

- The glass that is used to make optical fibers is ultraclear. So, it has less attenuation and can be used for long-distance communications.

- Glass fibers are more durable and can be used in wet and corrosive environments.

- Glass fiber is capable of transmitting a wide spectrum of 200-2200nm. In other words, it is capable of transmitting not only visible light but also UV and infrared rays.

- Some glass fibers are specially built to work with vacuum environments.

Disadvantages of glass optical fibers

- Product cost and installation costs are more expensive.

- The mechanical handling of glass optical fiber is difficult. It can break if not handled properly.

- Highly trained technicians are required to install glass optical fibers, and tools and equipment are more expensive.

- It requires high-technology light sources for glass optical fibers because its core diameter is minimal.

Plastic optical fiber

Plastic optical fiber (POF) is similar to glass fiber in structure and working principle. The fiber core is made from plastic strands, and the cladding is made with different grades of plastic. Plastic fibers are mainly fabricated using Poly Methyl Methacrylate (PMMA), also known as acrylic.

Plastic optical fibers came into use after glass optical fibers. It is commonly used as multimode fibers. Plastic fibers are widely used in home networking, digital appliances, and other short-distance, low-speed applications. Most plastic optical fibers use green or red light that is easy to see, and there is no harm even to the naked eye.

Advantages of plastic optical fiber

- The material cost of plastic fiber is low, and its accessories, tools, and equipment are also not expensive.

- There is no need for trained skills to install and use plastic optical fibers.

- Plastic optical fiber is easy to handle and able to bend more without breaking.

- Plastic optical fibers have the ability to withstand shock and unstable environments.

- We cannot manipulate the properties of glass, but we can control the properties of plastic in making fiber.

- Plastic fibers let less signal attenuation than glass fibers. Attenuation is caused by the inherent material properties of the fiber, such as absorption and scattering.

Disadvantages of plastic optical fiber

- Plastic optical fibers cannot be used for long distances because signal attenuation and dispersion increase when used over long distances.

- POF can not be used in high-temperature environments.

- POF can transmit only a narrow spectrum of visible light between 400 – 700 nm.

Glass-plastic optical fiber

Glass-plastic optical fibers have a glass core and plastic cladding. This plastic cladding serves as a protective layer for the glass core. So, there is no coating in glass-plastic optical fibers, but it is on all glass fibers.

Glass-plastic optical fibers are also known as plastic-clad silica (PCS) or sometimes hard-clad silica (HCS) fiber. HCS fibers are similar to PCS fibers, but their core or cladding is made with other materials. It is made using polymer or other stronger materials than other fiber cladding materials.

Plastic-clad silica fibers are usually used in industrial sensing applications and medical applications. Hard-clad silica fibers are generally used in factory automation and industrial workplaces. The reason why HCS fibers are used in these factories is that they can tolerate shocks.

Glass optical fiber vs plastic optical fiber

| Glass optical fiber | Plastic optical fiber |

|---|---|

| Less flexible | More flexible |

| Less attenuation | More attenuation |

| Small core diameter | Big core diameter |

| Have a large numerical aperture | Have a narrow numerical aperture |

| More expensive | Less expensive |

| Mechanical handling is difficult | Mechanical handling is easy |

| Can be used in higher temperature range | Cannot be used in a higher temperature range |

| Using for long-distance communications | Using for short-distance communications |

| Transmits a wide spectrum range | Transmits a narrow spectrum range |

Conclusion

Optical fibers fall under three material types—glass, plastic, and glass-plastic hybrids. Fabrication prioritizes compatibility for thin flexibility and transparency to preferred transmission windows.

Glass fibers employ ultra-pure, ultra-clear silica through controlled impurity addition to tailor refractive indices between core and cladding. They exhibit minimal attenuation over long hauls but require technical expertise and incur higher costs.

Plastic fibers like PMMA provide affordable installation but suffer higher attenuation over shorter reaches. Permissive bending eases deployment, yet temperature sensitivity constrains environments.

Glass-plastic designs marry glass cores’ transmission qualities with plastic claddings’ ruggedness. Sectors applying medical sensing or industrial automation leverage such robustness.

Material optimization strategizes properties suiting varied contexts. While glass suits telecommunications best, plastic caters better to building cabling. Hybrids find niches by synergizing both material virtues. Proper selection matches fiber type to stipulated conditions and performance needs.

FAQ

What are the three material used for making optical fibre?

The three materials for making optical fiber are silica (SiO2), plastic, and fluoride-based compounds. Silica is the most commonly used material due to its low attenuation. Plastic fibers are used in short-distance communication systems. Due to their unique optical properties, fluoride-based fibers are used in specialized applications, such as infrared spectroscopy.

What two materials can be used for core of optical fiber?

The two materials that can be used for the optical fiber core are glass and plastic. Glass is the most commonly used material for the optical fiber core, while plastic is less common. The core is the central part of the fiber through which light travels, and it has a diameter of between 50 and 125 microns.

How many types of fiber are classified based on mode?

There are two types of fiber classified based on mode: single-mode fiber (SMF) and multimode fiber (MMF). Single-mode fiber supports only one mode of light propagation, while multimode fiber supports multiple modes of light propagation.

What are the two types of optical fiber based on refractive index variation?

The two types of optical fiber based on refractive index variation are step-index fibers and graded-index fibers. Step-index fibers consist of a core surrounded by cladding with a single uniform index of refraction. Graded-index fibers have a core with a varying refractive index, which decreases gradually from the center of the core to the cladding.

What are the 3 general categories optical fiber is grouped into?

The three general categories that optical fiber is grouped into are based on the following parameters: material used, number of modes, and refractive index profile. Based on the material used, optical fibers are divided into two categories: glass and plastic. Based on the number of modes, optical fibers are classified as single-mode fiber (SMF) and multimode fiber (MMF). Based on the refractive index profile, optical fibers are classified as step-index fibers and graded-index fibers.