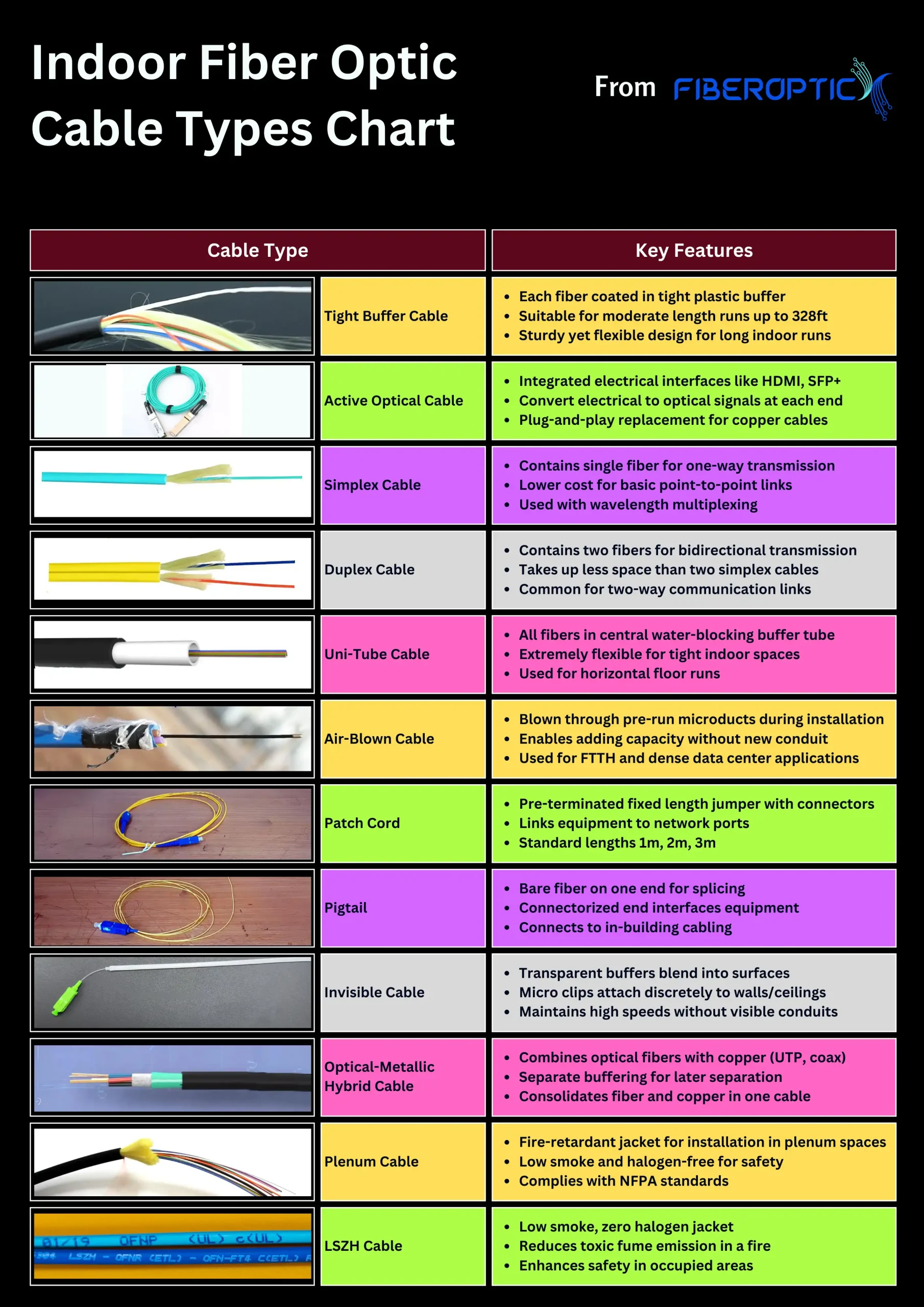

Indoor cables connect devices within homes, office buildings, data centers, and other interior spaces. Selecting the right indoor optical fiber cable depends on factors like transmission distance, space constraints, and building codes. This guide explores common indoor cable varieties and their distinct attributes when wiring rooms or structures for high-speed fiber optic links.

While outdoor cables endure much harsher abuse from weather and other conditions, indoor cables still face demands like tight bends, compression under carpets or ceilings, dust and dirt exposure near floors, and potential fire hazards. Choosing an optimal cable construction for each unique situation results in faster, simpler installation and a reliable network lifespan.

We’ll survey specialized indoor cable types and provide tips on selecting the proper cable to match your building requirements. Factors like fire rating codes, fiber type needed, and installation method help determine the ideal choice. Matching cable capabilities to space and network expectations makes deploying smooth, long-lasting fiber connections easy.

Table of Contents

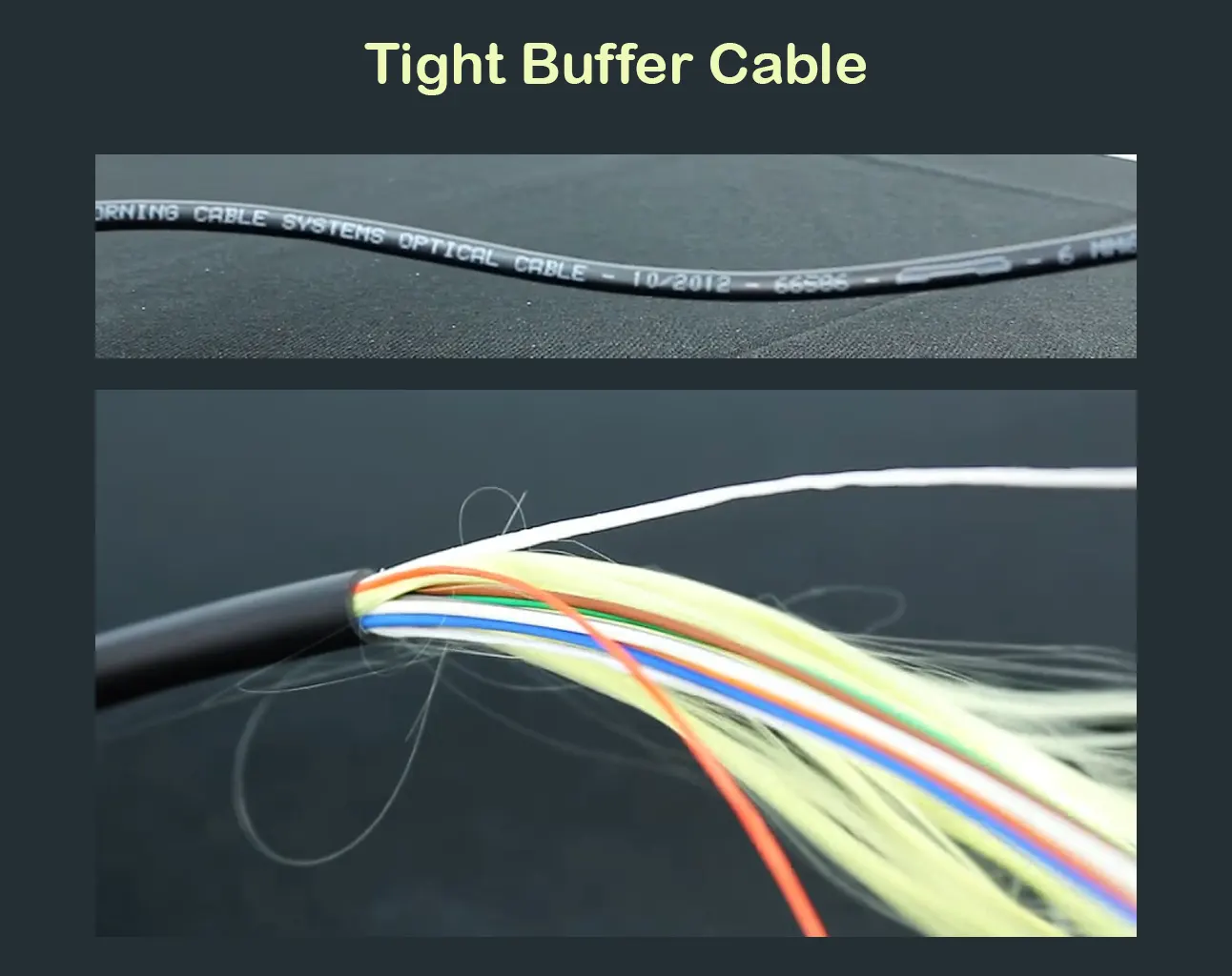

Tight Buffer Cable

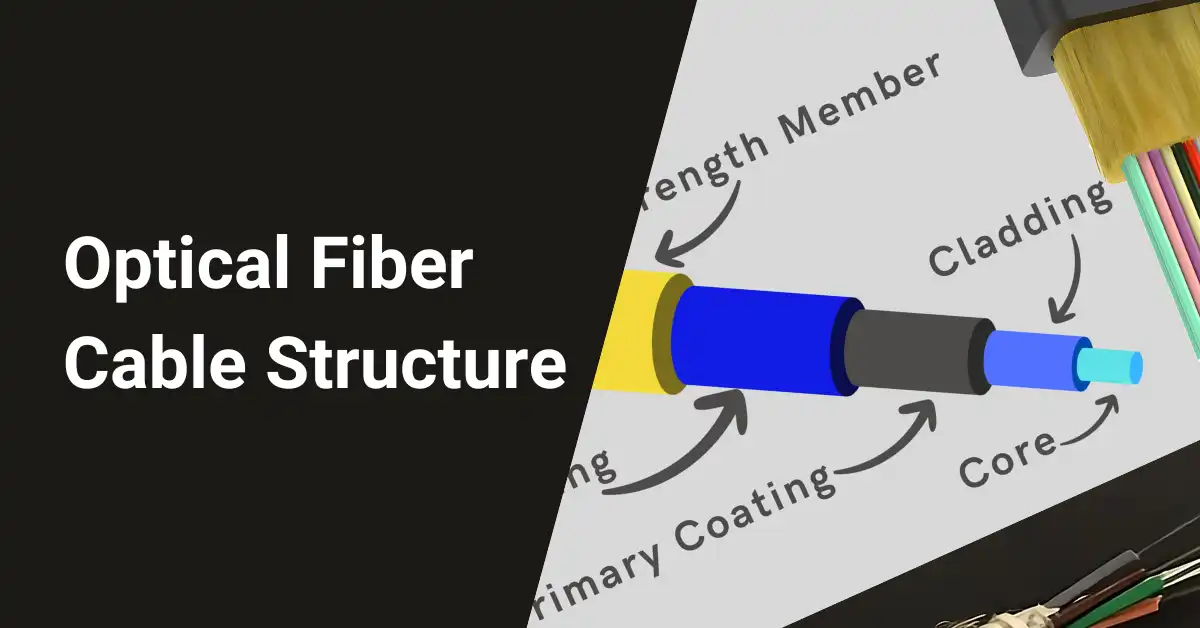

A tight buffer cable contains each fiber coated in protective plastic buffers rather than loose buffer tubes. The buffers are surrounded by Kevlar yarns or fiberglass for strength.

Tight buffer cables are optimally suited for moderate-length networks like LANs or WANs. Their sturdy yet flexible design also makes them good for long indoor runs, direct burial, and underwater use. They are easier to install than loose tube cables since there’s no gel filling to clean. However, they typically don’t have as high fiber counts.

- Tight buffer cables wrap each fiber in a protective 900-micron plastic buffer layer instead of using larger common buffer tubes holding multiple fibers.

- The individual tight buffers resist compression that could damage the thin glass fiber inside.

- Buffers are then bundled together and wrapped by Kevlar yarns or fiberglass strands, providing tensile strength.

- This durable yet maneuverable construction suits moderate-length networks under 328 feet.

- Tight buffer performs well in long indoor runs, direct burial, and underwater settings.

- No troublesome gel fill makes for effortless fiber access and cleaner splicing than loose tubes.

- Typical indoor applications include optical fiber distribution and links between building floors.

Tight buffer cables provide sturdy yet agile fiber protection for navigating congested indoor spaces. While not the cheapest or highest fiber count choice, their balance of strength and flexibility makes connecting equipment through ceilings, walls, and floors easier. For accessible fiber connections under 328 feet, tight buffer cables should be strongly considered.

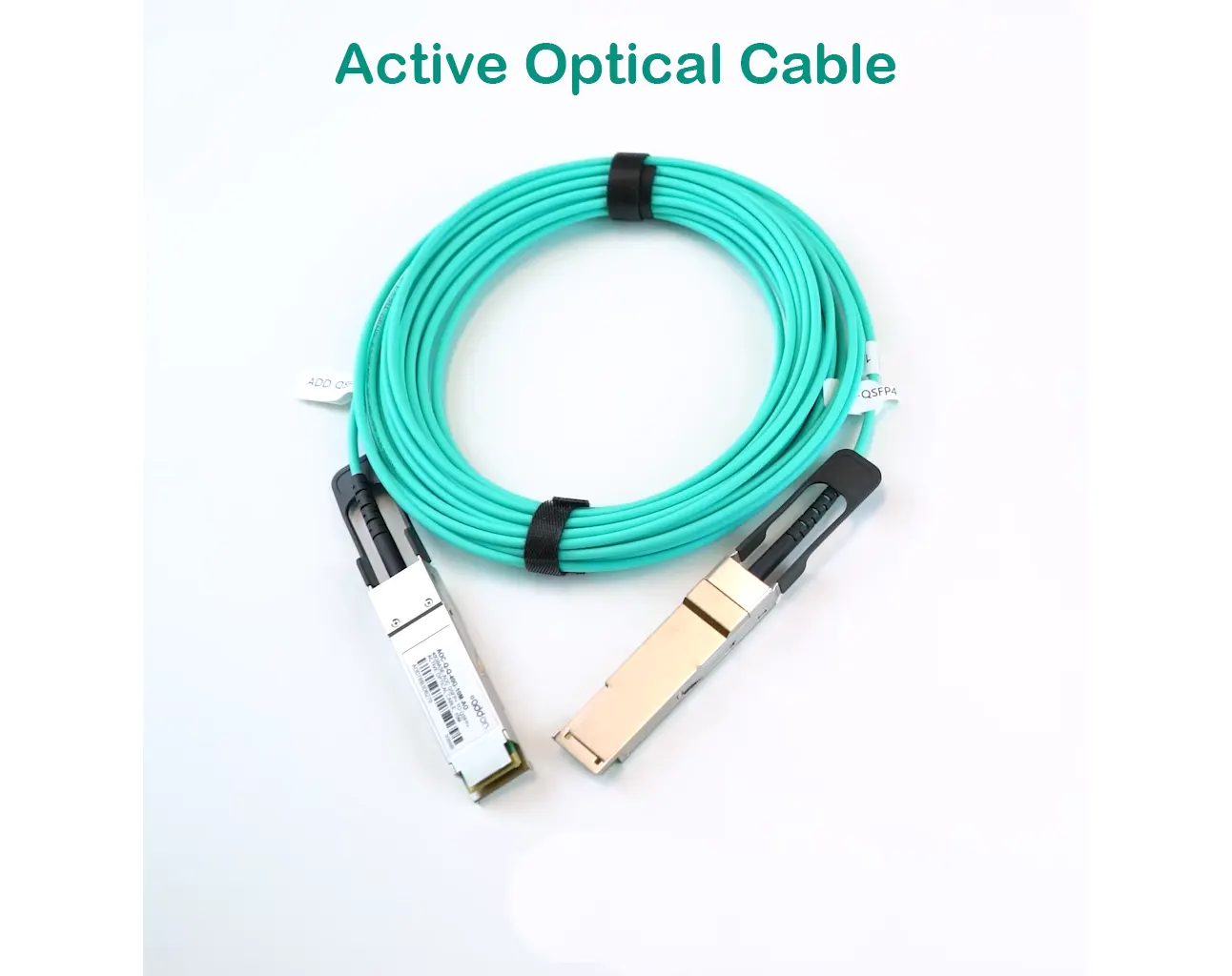

Active Optical Cable

An active optical cable (AOC) is pre-terminated with electrical interfaces like HDMI, DVI, SFP+, and QSFP+ external to the fiber optic cable. These integrated optoelectronic modules convert electrical signals to light and back at the cable ends.

AOCs are a simple, convenient solution when the “same electrical inputs as a copper cable” are needed, but fiber optic transmission offers advantages like longer distances, less EMI interference, and higher bandwidth. AOCs see use for conference room presentations, data center connections, and digital signage.

- AOCs embed powered optoelectronic transceivers within connector ends.

- These modules convert incoming electrical signals to light for fiber optic transmission.

- Common integrated interfaces include SFP, HDMI, DVI, VGA, SFP+, and QSFP+.

- The modules operate bidirectionally, translating optical signals back into electrical at reception.

- This allows AOCs to directly replace copper cables like HDMI or Ethernet.

- AOCs avoid the possibility of EMI interference with copper while enabling longer link distances.

- Typical applications include conference room presentations, data center connections, and digital signage.

AOCs act as plug-and-play fiber optic cable assemblies with built-in protocol conversion circuitry. Rather than calling for additional hardware, AOCs conveniently package cable and signal translation together to bridge between equipment.

Simplex Cable

A simplex cable contains just a single fiber for one-way, point-to-point transmission. Simplex cables are a lower-cost option when only a single transmit or receive line is required between devices, such as with multiplexing. As the simplest fiber cable construction, they offer an affordable option when lighting requirements permit:

- Simplex uses only one fiber strand rather than multiple parallel lines.

- This solitary glass fiber carries a signal in one direction, from transmitter to receiver.

- Without paired fibers, communication flows one way instead of bi-directionally.

- Simplex works for connecting devices needing just a transmit or receive line.

- They also suffice when using wavelength division multiplexing (WDM).

- With WDM, different wavelengths encode multiple data streams simultaneously over one fiber.

- Simplex cables cost less since they employ the minimum materials.

So simplex cables present a low-cost fiber connection for basic point-to-point communications needing just upstream or downstream capacity rather than simultaneous bidirectional transfer. Just be aware of their single-fiber limitations depending on networking needs.

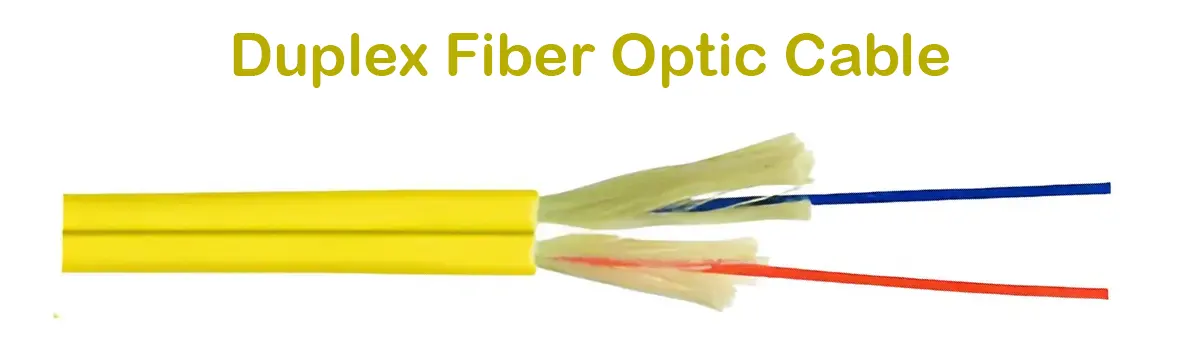

Duplex Cable

A duplex cable integrates two fibers in parallel for simultaneous bidirectional transmission. This consolidated cable takes up less space and simplifies handling compared to two separate simplex cables. Duplex cables are common for two-way communication links.

- Duplex cables contain two separate fiber strands bundled together.

- One fiber carries signals in one direction, and the other fiber transmits the opposite way.

- This allows devices at both ends to communicate concurrently.

- Duplex cables take up less space vs. two individual simplex cables.

- Having both fibers joined in one jacket eases cable handling.

- Joining transmit and receive lines reduces confusion over which fiber connects which endpoint.

- Duplex cables are ubiquitous for two-way communication links.

- Usage examples include telephone networks, Ethernet connections, and fiber channels.

Duplex cables enable concurrent bidirectional transmission crucial for technologies like networking and telephony. By providing dedicated optical lanes in both directions, they prevent sent and received data from interfering, unlike alternatives like wireless networking.

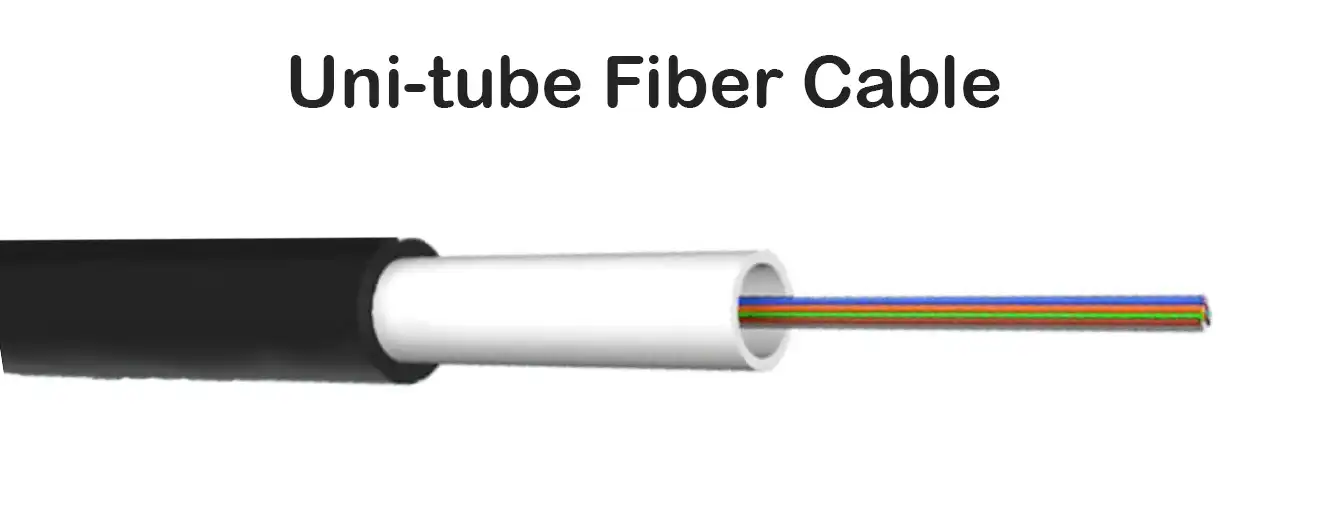

Uni-Tube Cable

In a uni-tube cable, all fibers reside together in a central, water-blocking buffer tube. The small tube helps create an extremely flexible cable well-suited for tight indoor spaces. Uni-tube cables excel in horizontal floor runs with lots of bends.

- A central plastic buffer tube houses all individual fibers.

- The uni-tube gets filled with water-blocking gel or powder to avoid moisture damage.

- Optical fibers reside loosely rather than being stranded to a central strength member.

- This loose structure makes inserting multiple fibers easier during manufacture.

- It also enables superb flexibility despite the dense fiber packing.

- The small circular profile aids navigation through tight indoor spaces.

- Typical indoor applications include horizontal floor runs with many bends.

- Utilities also use uni-tubes to route fiber to endpoint equipment like routers.

Uni-tube cables provide versatile fiber connectivity and unhindered flexibility to reach challenging indoor areas. Consolidating fibers into a lone buffer tube streamlines cable construction. A uni-tube cable eases the process of snaking fiber through cramped rooms and packed ceilings.

Air-Blown Cable

Air-blown cables blow through small ducts during installation, enabling faster, simpler adding of capacity. Lubrication reduces friction. Air-blown fiber sees frequent application in FTTH access networks and high-density data centers to supply additional connectivity as needed.

- Air-blown cables blow through pre-run micro ducts during deployment.

- Compressed air propels the lightweight cable through small ducts.

- Installers use mechanical blowers with air pressures up to 145 PSI.

- The air-blown installation enables faster, simpler capacity expansion.

- It also reduces the extensive construction of new conduit runs.

- Cables feature loose buffer tubes holding countless fibers.

- The ripcords allow easy mid-span access if needed.

- Lubricants like paraffin oil or polyethylene flakes reduce friction.

- This cuts abrasion and drag when pulling long cable lengths.

- Typical applications include FTTH access networks and high-density data centers.

Air-blown fiber often lowers installation costs in multifiber builds. Running micro ducts beforehand simplifies inserting additional capacity later as needed. For core infrastructure meant to support growth via extra connections down the road, air-blown cable makes excellent fiscal sense.

Patch Cord

A patch cord is a pre-terminated, fixed-length jumper cable with connectors like LC, SC, MTRJ, ST, FC, or MU on both ends. Patch cords plug devices into fiber optic network ports for quick connection and disconnection. They are integral components in linking equipment.

- Patch cords feature standard connectors on both ends.

- Common connector types used include:

- LC, SC, MTRJ

- ST, FC, MU

- Patch cords are manufactured in fixed, standardized lengths.

- Typical lengths used are 1m, 2m, and 3m.

- Field technicians heavily rely on patch cords.

- They joint equipment into structured cabling systems.

- Patch cords integrate into cabling distribution centers.

- They also patch switch ports to respective network devices.

- Durable patch cords withstand frequent plugging and unplugging.

- Using factory-made cords saves labor over custom cable assemblies.

Pre-connectorized optical patch cords make establishing fiber links between hardware and infrastructure fast and consistent. Keeping an inventory of varied cords for each connector type avoids attention-diverting field terminations when racking gear. For rapid fiber connections, durable patch cords excel.

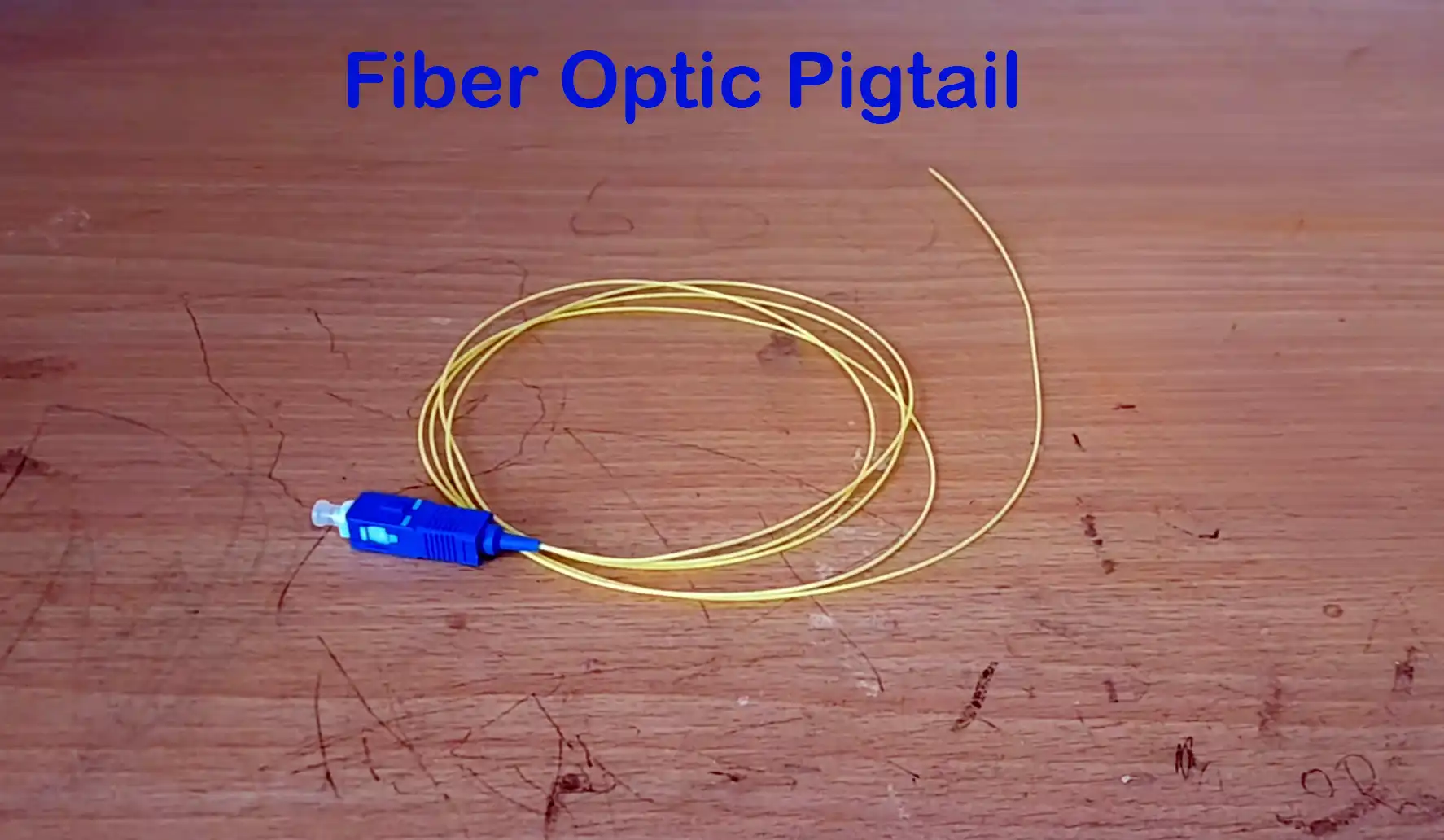

Pigtail

A pigtail has a factory connector on one end but leaves the other end bare for splicing. Pigtails interface equipment to installed cable runs by fusion splicing. They save time and cost when coupling transmission hardware to the optical cabling plant.

- Pigtails feature a permanent connector on one end.

- The other end leaves exposed fiber to fusion splice.

- Pigtails connect to premises cables via splicing trays.

- This avoids the need to connectorize raw building fiber.

- Instead, the factory-terminated pigtail handles that end.

- Pigtails then plug into optical hardware ports.

- This shifts connectorization workload offsite.

- It also takes advantage of automated polishing tools.

- The resulting connections have under 0.1 dB loss.

- Pigtails save big on technician labor and craftsmanship.

- Their flexibility also aids equipment shuffling.

Pigtails simplify integrating devices to structured cabling by handling connectorization factory-side. Pigtails bridge devices and builds fiber reliably while reducing workspace equipment needs.

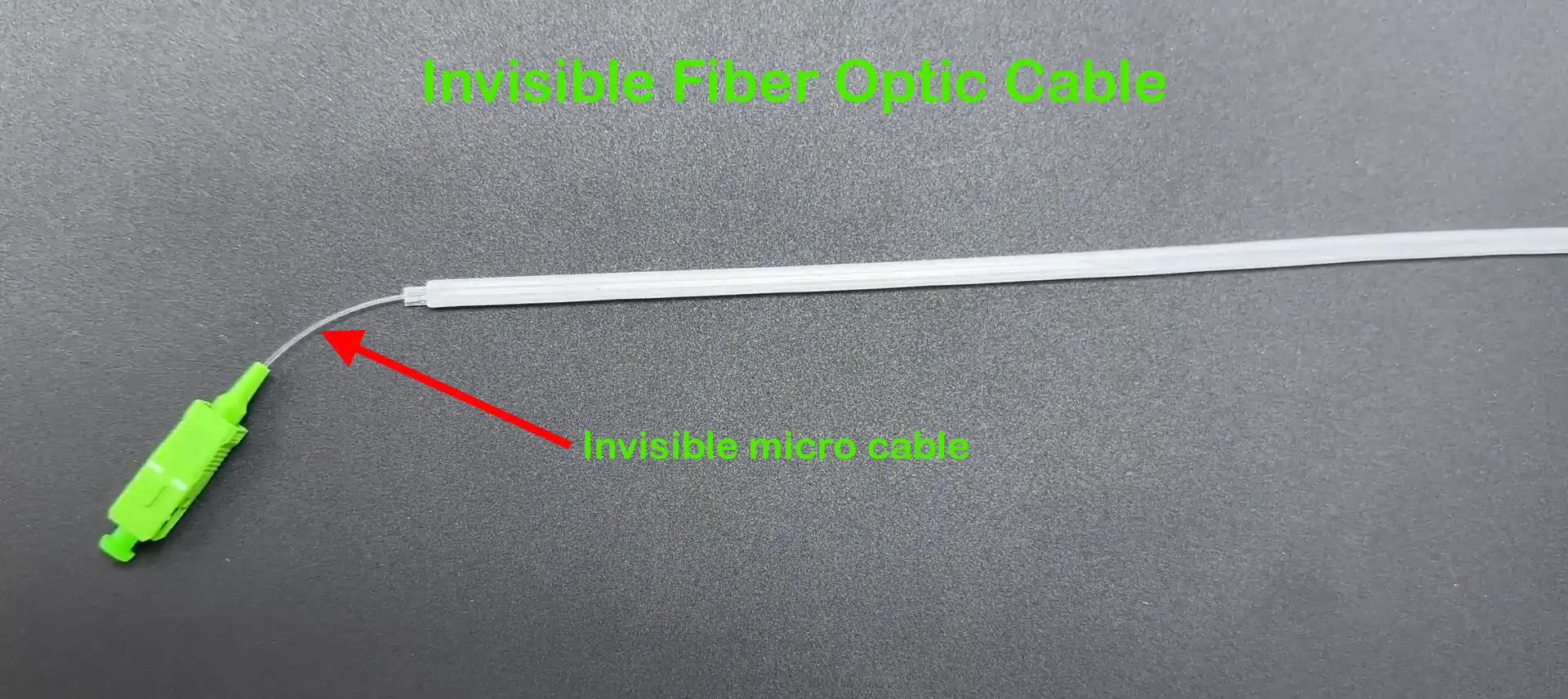

Invisible Cable

Invisible micro cables with transparent buffer tubes attach discretely to walls and ceilings using ultra-bend-insensitive fibers and adhesive clips. These unobtrusive cables maintain high broadband speeds for indoor networks without running noticeable conduits. They feature swift, non-destructive applications.

- Invisible fiber uses transparent buffers blending into surfaces.

- Diameters slim down to 0.9mm to vanish from sight.

- Micro clips or adhesives attach cable to walls and ceilings.

- This avoids surface marring that attracts attention.

- Barely noticeable fibers do not detract from the decor.

- Flexible bend-insensitive fibers prevent transmission loss.

- Simple installation avoids debris and hassles of conduits.

- Removal for redecorating leaves no visible damage.

Transparent indoor cabling and slim dimensions ensure fiber installs remain covert. Invisible fiber dissolves into building materials for upgraded bandwidth without altering aesthetics. Unseen fiber cables please occupants while opening any area to networking.

Optical-Metallic Hybrid Cable

A fiber optic-metallic hybrid cable combines optical fibers and electrical copper conductors in an integrated package. Typical elements include UTP or coaxial providing Ethernet connectivity alongside fibers for backhaul needs exceeding copper’s limits. The separate buffering eases later separation at endpoints.

- Hybrid cables combine glass fiber strands alongside metal conductors.

- Typical conductive components are UTP, coaxial, or 4-pair cabling.

- These handle standard electric Ethernet signaling.

- Optical fibers provide backhaul capacity beyond copper limits.

- A central strength member bears load during installation.

- Outer insulation segregates conductors and buffers.

- This simplifies separating elements at either end.

- Applications include building routers gathering both media types.

- Hybrid consolidation cuts labor versus two cable pulls.

Hybrid fiber-metal cables reduce conduits and work compared to separate runs. Lightweight fiber participates alongside legacy electric signaling in one compact, multipurpose package.

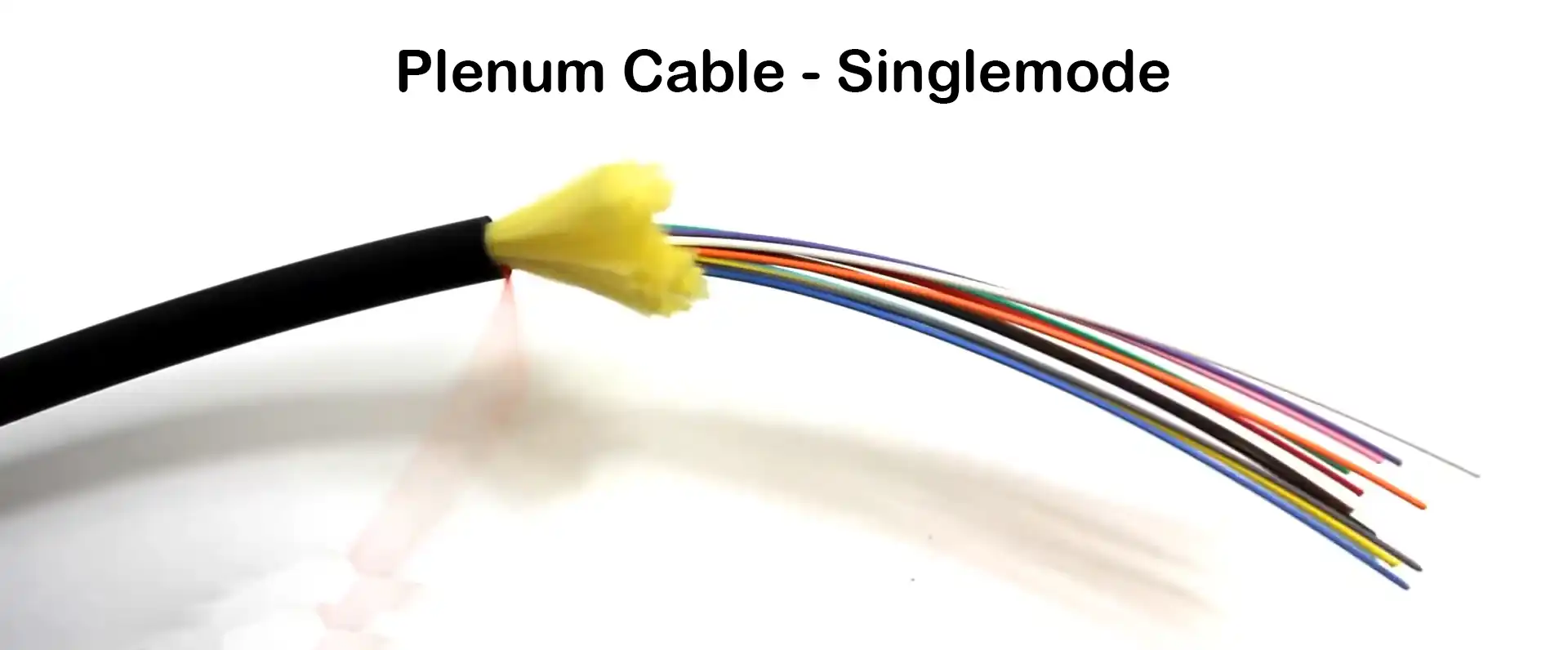

Plenum Cable

Plenum cables utilize jackets with low-smoke, fire-retardant plastics meeting NFPA safety standards for installation in building circulation plenum spaces like above drop ceilings. Compliance ensures they resist spreading flames to protect structures and occupants if combustion occurs.

- National Fire Protection Association (NFPA) fire codes demand cabling to reduce flames.

- Public circulation areas above drop ceilings are classified as “plenum” spaces.

- Since hot gasses flow freely here, plenum cables avoid fueling blazes.

- Plenum jackets utilize FEP plastics to contain fires.

- Low-smoke, zero-halogen (LSZH) materials also work.

- These finishes produce minimal smoke to delay occupant distress.

- Improved visibility assists in safe emergency evacuation.

- Resisting fire better also helps with structural protection.

Approved plenum cable ensures public building safety by localizing rather than spreading fires. Compliance gives inspectors confidence in fire preparedness for at-risk spaces. Guarding plenum areas with certified low-flame cabling defends both lives and property.

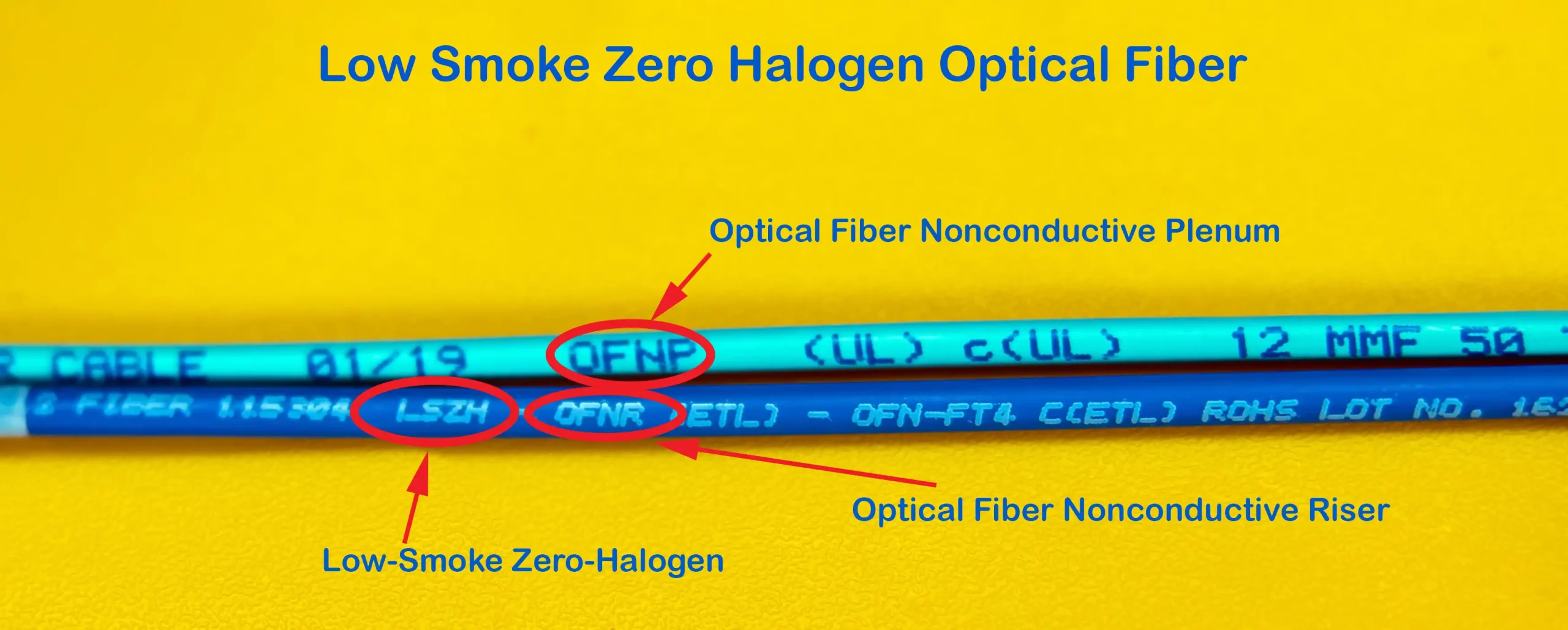

LSZH Cable

LSZH indoor cables also implement special low-smoke, zero-halogen jackets that minimize the release of toxic fumes when burned. The emissions and environmental impact are lower than standard PVC insulation if exposed to fire. LSZH cables enhance safety in enclosed occupied areas.

- LSZH stands for “low-smoke, zero-halogen”.

- Unlike PVC, LSZH jackets deter fire less during a blaze.

- LSZH instead focuses on reducing fume dangers.

- The materials emit limited smoke when burned.

- This prevents occupants from getting blinded or choked.

- LSZH also eliminates halogens from being released.

- Halogens like chlorine and bromine threaten health.

- Corrosive gases also damage electronics.

- Popular LSZH ingredients include polyethylene or polystyrene.

- These improve safety in occupied areas.

LSZH uniquely targets the risky byproducts of burning cables rather than the fire spread itself. Though LSZH does resist flames, its chief purpose is limiting smoke and toxic emissions in a fire’s presence to protect human health.

Conclusion

Indoor fiber optic cables transport high-speed signals between devices inside buildings utilizing different cabling types to match needs. Tight buffer cables provide durability and flexibility when installing links across floors.

Simplex and duplex cable designs suit basic unidirectional or bidirectional networking. Specialized air-blown fiber enables smoothly upgrading capacity for future growth. Invisible wall-mounted cables allow discreet fiber connections without aesthetic disruption.

Critical buildings leverage plenum and LSZH cables to promote fire safety by controlling damage and smoke. Optimizing needs for cable capabilities makes indoor fiber deployments easier while serving reliability over decades.

Here are the important points of the Indoor fibre optic cable types that we discussed.

FAQ

What are the three main types of indoor fiber optic cables?

∎ Simplex: One fiber for single-direction data transmission.

∎ Duplex: Two fibers for bi-directional data transmission (most common).

∎ Breakout: Bundle of multiple fibers (4, 8, 12+) for multi-device connections.

What are the advantages of using fiber optic cables indoors?

∎ Faster data transmission speeds compared to copper cables.

∎ Lower signal loss over longer distances.

∎ Immune to electromagnetic interference (EMI).

∎ Smaller and lighter cables for easier installation.

Can I use fiber optic cable in my house?

Technically yes, but it’s not common due to the higher cost and complexity compared to copper for typical home internet needs. Fiber installation also requires specialized tools and skills.

What are the different types of indoor fiber optic cable jackets?

∎ OFNR: Standard, non-flame retardant for non-plenum spaces.

∎ LSZH: Flame retardant and low smoke emission for plenum spaces (critical for safety).

∎ Armored: Additional strength and protection for demanding environments.

What is the difference between 900 and 250-micron fiber?

The number refers to the diameter of the outer cable cladding. 900 micron is thicker and more rugged, often used for outdoor applications. 250 microns is thinner and more flexible, ideal for indoor applications.

Which type of fiber optic connector is most common indoors?

∎ LC (Lucent Connector): Compact and easy to use, commonly found in data centers and networking equipment.

∎ SC (Subscriber Connector): Simple and reliable, often used for FTTH (Fiber To The Home) installations.

∎ MTP/MPO: Multi-fiber connector for high-density applications.