Bending loss is one of the properties of fiber loss, and flexibility is one of the most important benefits of modern optical fiber. Optical fibers must be able to bend because they are drawn in different places. Bending losses are non-linear losses that result in attenuation in optical fiber. There are two types of bending losses in optical fiber.

- Micro bending loss

- Macro bending loss

Table of Contents

Micro bending loss in optical fiber

Micro-bending loss is the loss that happens when the optical fiber axis is slightly distorted. Due to the geometrical imperfections of the core cladding, there may be microscopic bulges or depressions in the fiber axis. Initially, the laser beam starts out moving at a critical propagation angle, which changes when it hits these flaws and is reflected back.

Because of this phenomenon, the condition for total internal reflection is no longer fulfilled, and some beams are refracted, which means they leak out of the core of the fiber. This is what causes the micro-bending loss.

What causes micro bending loss and how to reduce it

- During the manufacturing process of the fiber

There is no other way to reduce micro-bending loss than to let manufacturers improve the quality of their optical fiber. But technology for making fibers has come a long way, and micro-bending loss is no longer a big problem. It is safe to presume that micro-bending loss during manufacturing is factored into the specified total attenuation.

- Due to improper handling of the fiber

In addition to the micro-bending loss that happens during the manufacturing process, there is another reason for it. It can be a micro bulge or depression caused by direct mechanical pressure on the optical fiber. Also, optical fibers can be micro-bent when they are pressed while hot. So, when using it, you should be very careful when installing and maintaining optical fiber cable.

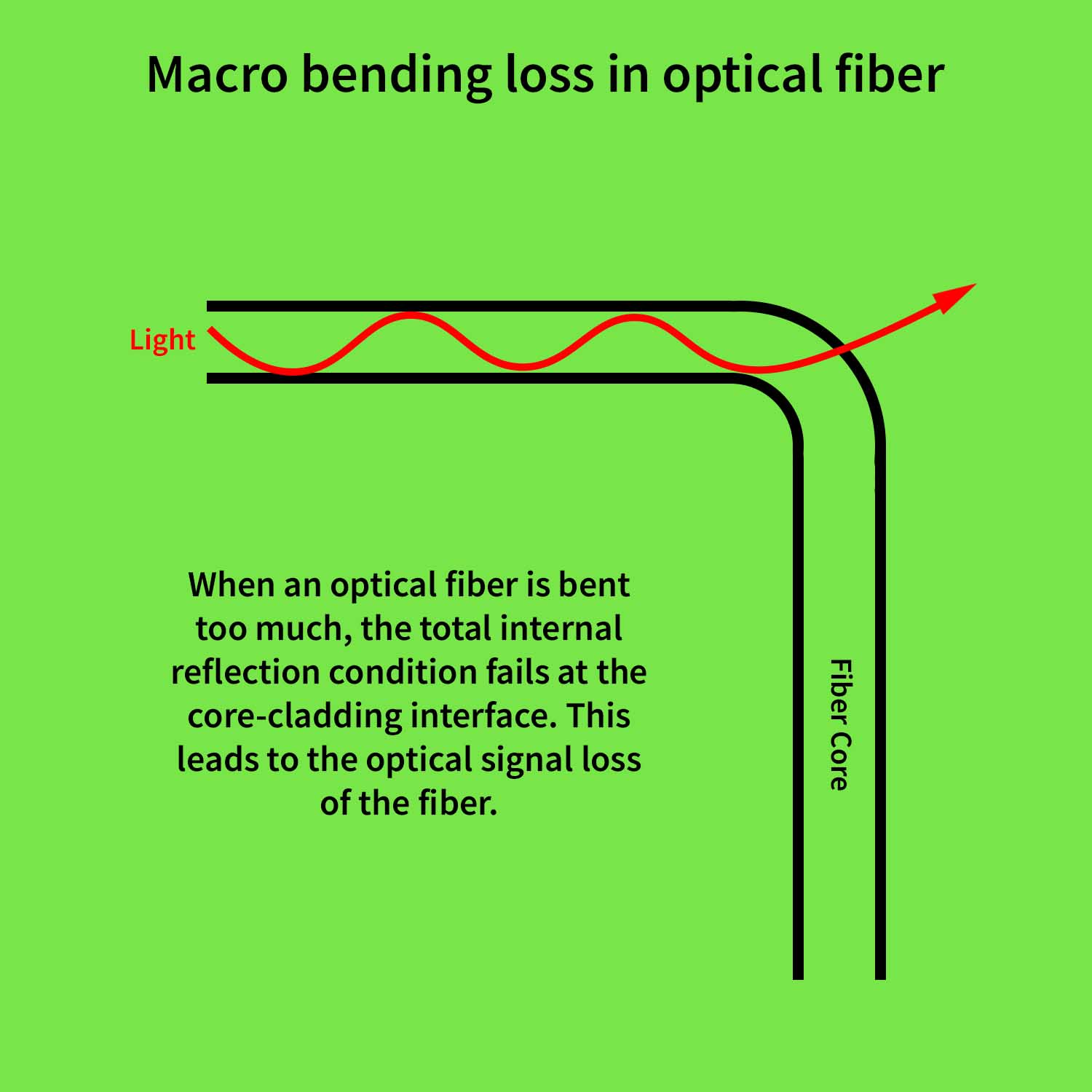

Macro bending loss in optical fiber

Macro bending loss is the fiber loss caused by the whole optical fiber axis bent into a large radius of curvature relative to the fiber diameter. The optical fiber’s straight or flat part forms a critical propagation angle with the optical fiber’s axis.

However, the propagation angle of the same beam at the bent place of the fiber is greater than the critical value. The result is that the condition for total internal reflection cannot be fulfilled in the bent fiber, so some of the beams will leak out of the fiber core.

So, the amount of optical power at the destination is less than the power that enters the optical fiber from the light source. That is, the optical power loss will happen when a macro bend happens in an optical fiber.

If the radius of the macro bend is big enough, it won’t cause a lot of radiation to be lost. But when fibers are bent below a certain radius, a lot of light power is lost because of radiation.

What causes micro bending loss and how to reduce it

Sometimes, we find macro bending loss in a splice tray inside the closures, termination boxes, or patch panels. It can also be found in a fiber cable bent into coils in a fiber network pole or manhole.

The best way to prevent bending loss in optical fiber is to avoid sharp bends. The manufacturer gave the banding radius for their fiber, and we should follow their instructions.

Also, there’s a rule of thumb for the minimum bend radius.

- For long-term use, the bending radius of fiber should be more than 150 times the diameter of the fiber cladding.

- For short-term uses, the bending radius of the fiber should be at least 100 times bigger than the diameter of the cladding.

Calculate the bend radius using our calculator

How can bending loss be minimized?

Bending loss in optical fibers is caused by the leakage of light out of the fiber core when the fiber is bent. The amount of bending loss depends on the radius of curvature of the bend and the wavelength of light. There are many ways to minimize bending loss in optical fibers.

Here are 8 essential steps to minimize the bending loss in optical fibers:

- Use bend-insensitive fiber. BIF is specially designed to maintain signal integrity when bent. It has a larger core and a gradual refractive index for tighter bends.

- Increase the bend radius. The larger the bend radius, the less curvature and thus less light loss from the core.

- Apply a compressible jacket. The jacket provides cushioning that reduces micro-bending losses when the fiber is flexed.

- Avoid sharp bends. Sharp bends cause more light to leak out of the fiber core than gradual bends.

- Careful handling. Handle and install fibers carefully to prevent kinks or sharp bends that increase losses.

- Proper cable management. Use cable trays and racks to ensure fibers are not excessively bent during installation or use.

- Reduce refractive index difference. A smaller difference allows light to propagate more easily with less loss.

- Widen the core diameter. A wider core allows light to travel through with less scatter.

The key is to provide the fiber with as gentle and gradual a pathway as possible for light traveling through the core by using BIF, avoiding sharp bends, and widening the core. Careful handling and proper cable management also go a long way in minimizing bending losses.

Summary

Bending introduces non-linear attenuation from light redirected beyond critical propagation angles. Microscopic deformations cause micro-bending loss, while macro bends exceed the core-crossing threshold.

Manufacturing quality curbs intrinsic micro distortions, yet installation necessitates attenuation prediction. Improper handling induces microscopic pressure variations, refracting scattered waves.

The macro loss depends on curvature severity—gentler arcs preserving power—necessitating minimum bend radii adherence. Specialized bend-insensitive fiber, compressible jacketing, gradual pathways, and widened cores resist leakage by maintaining gradual refraction differences.

Protocols prioritize careful manipulation and cable routing through trays to prevent kinking. Refinement in dopant selection and graded refractive profiles bolster macro-bend tolerance.

While micro reductions necessitate stringent production monitoring, macro techniques center on installation maneuvering to guarantee rugged flexibility and withstand deployment without compromised signal conductance. Adherence forestalls losses, enabling extended haul connectivity.

FAQ

What are the two types of bending losses?

The two types of optical fiber bending losses are macroscopic loss and microscopic loss. Macroscopic loss occurs when the fiber is bent with a larger radius than its diameter, while microscopic loss occurs due to random microscopic bends of the fiber axis.

What causes bending loss?

Bending loss in optical fiber is caused by the deviation from the ideal straight-line light path through the fiber. When a fiber is bent, some of the light propagating through the core leaks out of the fiber due to the compromised total internal reflection.

What is the difference between macro and micro bending loss?

Macro bending losses occur when a fiber is bent on a larger scale, such as when wrapped around a spool or a corner. Micro-bending losses occur when small-scale fluctuations, such as vibrations or pressure changes, cause slight deformations in the fiber, resulting in signal loss.

What does micro bending losses in optical fiber depends on?

Micro bending losses in optical fiber depend on the geometrical imperfections of the core cladding, which may cause microscopic bulges or depressions in the fiber axis.

How can micro bending losses be reduced in the fiber?

Micro bending losses in optical fiber can be reduced by improving the quality of the optical fiber during manufacturing. This involves minimizing the geometrical imperfections of the core cladding to reduce microscopic bulges or depressions in the fiber axis.